Solution: Processing Aids

Processing Aids are substances added during the processing of materials such as plastics, rubber, and coatings to improve their flowability, processing performance, stability, and final product quality. These additives optimize the processing process, reduce friction, enhance flowability, and improve stability, helping to increase production efficiency and ensure product consistency. Our FORNAWAX, FORNAPLUS, and FORMOSA brand processing additives are specifically designed to meet the processing needs of various materials and are widely used in industries such as plastic processing, rubber molding, and coatings, helping to improve the processing performance and final results of materials.

-

FORNAWAX 3M-501

Overview

Polyethylene Wax Grafted with Maleic Anhydride (MAH)

Enhance the interfacial bonding between nylon PA66 and fiberglassBrand

FORNAWAX

Model No

3M-501

Industries

Solutions

Application

Enhance the interfacial bonding between nylon PA66 and fiberglass -

FORNAWAX 3V-203

Overview

Low Molecular Weight Ethylene-vinyl Acetate Copolymer Grafted Wax

Perfect for dispersion in carbon black systemBrand

FORNAWAX

Model No

3V-203

Industries

Solutions

Application

Perfect for dispersion in carbon black system -

FORNAWAX AC-2220

Overview

Linear Polyethylene Wax with Medium Viscosity

Excellent internal and external lubrication; good dispersionBrand

FORNAWAX

Model No

AC-2220

Industries

Solutions

Application

Excellent internal and external lubrication; good dispersion -

FORNAWAX XV-203

Overview

Low Molecular Weight Ethylene-vinyl Acetate Copolymer

Brand

FORNAWAX

Model No

XV-203

Industries

Solutions

Application

Specifications

Item Unit Typical Value / Properties Softening Point °C 101-107 Viscosity @140°C mPa·s 400-500 Hardness @25° 10-1mm ~3.0 Penetration 10-1mm <6 Density g/cm3 0.92 Acid Value mgKOH/g 13 Appearance White Powder -

FORNAWAX OL-10

Overview

Oxidized Polyethylene Homopolymer

Brand

FORNAWAX

Model No

OL-10

Industries

Solutions

Application

Specifications

Item Unit Typical Value / Properties Drop Melting Point °C 101 Viscosity @140°C cps 200 Hardness @25°C 10-1mm 3-6 Density g/cm3 0.93 Acid Value mgKOH/g 14-17 Appearance White Powder -

FORNAWAX OH-24

Overview

Low Molecular Weight Oxidized Polyethylene Wax

Brand

FORNAWAX

Model No

OH-24

Industries

Solutions

Application

Specifications

Item Unit Typical Value / Properties Softening Point °C 133 Viscosity @160°C mPa·s 8000-13000 Hardness @25°C 10-1mm ~1.0 Density g/cm3 0.99 Acid Value mgKOH/g 23-28 Appearance White Powder Size mm <1 -

FORNAWAX AC-2450

Overview

Low Molecular Weight Polyethylene Wax

Brand

FORNAWAX

Model No

AC-2450

Industries

Solutions

Application

Specifications

Item Unit Typical Value / Properties Softening Point °C 107 Viscosity @140°C mPa·s 400-500 Hardness @25°C 10-1mm >3.0 Density g/cm3 0.92 Appearance White Powder -

FORNAWAX AC-2030

Overview

Low Molecular Weight Polyethylene Wax

Brand

FORNAWAX

Model No

AC-2030

Industries

Solutions

Application

Specifications

Item Unit Typical Value / Properties Softening Point °C 106-110 Viscosity @140°C mPa·s 20-30 Hardness @25°C 10-1mm ~3.0 Penetration 10-1mm 1.0-3.0 Density g/cm3 0.92 Appearance White Powder

-

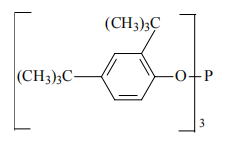

FORNAPLUS OX-168

Overview

Antioxidant

OX-168, a processing stabilizer for hydrolysis-resistant phosphites. As a secondary antioxidant, it can react with hydrogen peroxide produced by polymer oxidation during processing to prevent polymer degradation and prolong the antioxidant properties of the primary antioxidant.Brand

FORNAPLUS

Model No

OX-168

Industries

Solutions

Application

OX-168, a processing stabilizer for hydrolysis-resistant phosphites. As a secondary antioxidant, it can react with hydrogen peroxide produced by polymer oxidation during processing to prevent polymer degradation and prolong the antioxidant properties of the primary antioxidant.Chemical Name

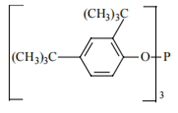

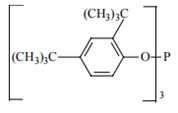

Tris(2,4-ditert-butylphenyl)phosphite

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 646.9 g/mol Melting Point ℃ 183-186℃ Product Forms White free-flowing powder Packing Specification 25kg/bag -

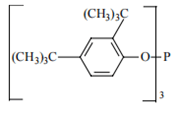

FORNAPLUS OX-B900

Overview

Antioxidant

OX-B900, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1076 and OX-168.Brand

FORNAPLUS

Model No

OX-B900

Industries

Solutions

Application

OX-B900, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1076 and OX-168.Chemical Name

20% OX-1076, 80% OX-168

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight OX-1076: 530.86 g/mol

OX-168: 646.9 g/molProduct Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-B225

Overview

Antioxidant

OX-B225, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Brand

FORNAPLUS

Model No

OX-B225

Industries

Solutions

Application

OX-B225, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Chemical Name

50% OX-1010, 50% OX-168

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight OX-1010: 1177.7 g/mol

OX-168: 646.9 g/molProduct Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-B215

Overview

Antioxidant

OX-B215, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Brand

FORNAPLUS

Model No

OX-B215

Industries

Solutions

Application

OX-B215, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Chemical Name

33% OX-1010, 67% OX-168

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight OX-1010: 1177.7 g/mol

OX-168: 646.9 g/molProduct Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-1098

Overview

Antioxidant

OX-1098, A highly efficient, non-discoloring hindered phenolic antioxidant, suitable for various organic substrates such as plastics, synthetic fibers, adhesives, and elastomers, with particular efficacy in polyamide plastics and fibers.Brand

FORNAPLUS

Model No

OX-1098

Industries

Solutions

Application

OX-1098, A highly efficient, non-discoloring hindered phenolic antioxidant, suitable for various organic substrates such as plastics, synthetic fibers, adhesives, and elastomers, with particular efficacy in polyamide plastics and fibers.Chemical Name

N, N’-hexane-1,6-diylbis(3-(3,5-di-tert.-butyl-4-hydroxyphenylpropionamide))

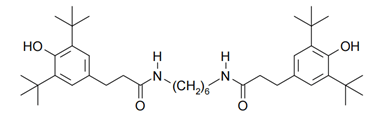

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 637 g/mol Melting Point ℃ 156-161℃ Product Forms White free-flowing powder Packing Specification 25 kg/bag -

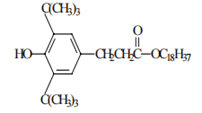

FORNAPLUS OX-1076

Overview

Antioxidant

OX-1076, An efficient, non-staining hindered phenolic antioxidant. Suitable for use in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates. Odorless, light-stable, and resistant to discoloration. It exhibits excellent compatibility with substrates, low volatility, and superior resistance to leaching.Brand

FORNAPLUS

Model No

OX-1076

Industries

Solutions

Application

OX-1076, An efficient, non-staining hindered phenolic antioxidant. Suitable for use in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates. Odorless, light-stable, and resistant to discoloration. It exhibits excellent compatibility with substrates, low volatility, and superior resistance to leaching.Chemical Name

Octadecyl-[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]

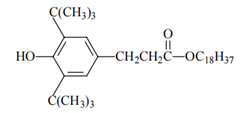

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 530.86 g/mol Melting Point ℃ 50-55℃ Product Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-1010

Overview

Antioxidant

OX-1010, An efficient, non-staining hindered phenolic antioxidant. It can be used in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates.Brand

FORNAPLUS

Model No

OX-1010

Industries

Solutions

Application

OX-1010, An efficient, non-staining hindered phenolic antioxidant. It can be used in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates.Chemical Name

Pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate)

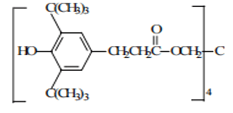

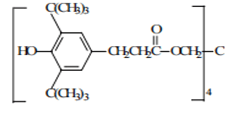

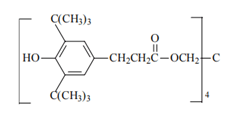

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 1178 g/mol Melting Point ℃ 110-125℃ Product Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-245

Overview

Antioxidant

OX-245, A highly efficient hindered phenolic antioxidant, extensively used in various polymers, synthetic fibers, elastomers, adhesives, waxes, oils, and fat-based products to effectively prevent thermal and oxidative degradation of these materials.Brand

FORNAPLUS

Model No

OX-245

Industries

Solutions

Application

OX-245, A highly efficient hindered phenolic antioxidant, extensively used in various polymers, synthetic fibers, elastomers, adhesives, waxes, oils, and fat-based products to effectively prevent thermal and oxidative degradation of these materials.Chemical Name

Ethylene bis(oxyethylene) bis-(3-(5-tert-butyl-4-hydroxy-m-tolyl)propionate)

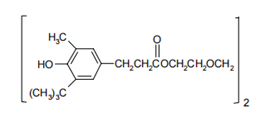

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 586.8g/mol Melting Point ℃ 76-79℃ Product Forms White free-flowing powder Packing Specification 20kg/bag

-

FORMOSA P-201

Overview

Processing Aid

General plasticization. Can be use in PVC system.Brand

FORMOSA

Model No

P-201

Application

General plasticization. Can be use in PVC system.Specifications

Appearance White Powder Bulk Density (g/cm³) 0.40 max Volatility (%) 1.0 max Average Particle Size(μm) 100-130 Particle Size(+60 /- 325mesh) 1% / 3%