FORNAX

Strategic Supplier – FORNAX

High-Performance Chemistry Driving Industrial Innovation

FORNAX Chemica, headquartered in Leverkusen—the heart of Germany’s chemical industry—originated as a German-Dutch joint venture. Upholding the tradition of European scientific research, the company focuses on the development and application of high-performance materials, continuously providing cutting-edge chemical solutions for the global plastics, coatings, energy, and agriculture sectors.

🌟 Focused on Innovation and Breakthroughs in High-Performance Materials:

We are committed to enhancing both industrial efficiency and material performance, with core technologies including:

- Engineering applications of functional polymers and environmentally friendly biodegradable materials

- Optimization of flow and dispersion in complex systems

- Phase-change regulation and thermal stability control

- Enhancement of optical properties and high-temperature color shift technologies

Key Product Lines:

FORNAWAX®

High-Efficiency Dispersant Series: Suitable for various systems including pigments, plastics, inks, and coatings.

- Enhances Uniformity of Particle Distribution

- Reduces Viscosity and Optimizes Processing

- Enhances System Stability and Color Performance

FORNAPLUS®

High-Performance Additive Series: Designed to improve material stability under high temperature, shear, and other demanding conditions.

- Enhances Thermal Stability and Antioxidant Performance

- Improves Flowability, Demolding, and Surface Quality

- Suitable for engineering plastics, high-fill systems, composites, and more.

Global Manufacturing Footprint:

FORNAX® boasts a worldwide manufacturing network with production facilities located in:

Germany, Belgium, Seychelles, Singapore, Japan, China, Vietnam, and Indonesia.

This global footprint ensures stable, rapid, and compliant product supply tailored to diverse markets and climatic conditions.

Application areas include:

🔗 FORNAX’s Commitment:

FORNAX Products

-

FORNAWAX XS-326

Overview

A modified polysiloxane product after surface treatment for:

● Polyolefins such as PE, PP

● Functional polymers such as PA6, PA66

● Filling base materials

● Industrial polymers

● MasterbatchesBrand

FORNAWAX

Model No

XS-326

Industries

Solutions

Application

● Improve processing fluidity of plastics and demolding performance.

● Reduce torque; reduce wearing of equipment and facilitate mold release.

● Reducing product defect rates.

● Significantly reduce friction coefficients and improve smooth performance.

● Improve surface gloss and enhance surface silk-like texture.

● Improve abrasion resistance and scratch resistance,

● Improve flame retardant performance;

● Reduce smoke density; and enhance the flame retardancy (high filling) material impact strength and surface gloss.

● Enhance good stability and prevent migration

● Reduces torque, improves melt index of wire and cable mixtures.

● Not recommended to use for transparent products. -

FORNAWAX XS-350

Overview

As organic silicon plastic processing aid with polarized groups at both ends; and as lubricatiing and dispersing agents for pigments and fillers:

● Polyolefins such as PE, PP

● Functional polymers such as PA6, PA66

● Filling base materials

● Industrial polymers

● MasterbatchesBrand

FORNAWAX

Model No

XS-350

Industries

Solutions

Application

Significantly disperse fillers and pigments:

● Significantly improve the dispersibility of fillers (such as flame retardants, glass fibers, etc.) during the extrusion process; thereby enhancing the flame retardant or mechanical properties of the products.

● Improve surface gloss and smoothness; eliminate surface defects caused by adding fillers (such as glass fibers); and reduce the defect rate.

● Increase the addition amount of fillers and reduce production costs.

Excellent lubricating performance:

● Increase speed of product extrusion; reduce defective rate; and improve the fluidity of plastic processing

● Reduce torque, and enhance mold release and demolding capabilities.

● Improve surface smoothness (hand feel), abrasion resistance, and scratch resistance of the products.

● Enhance self-cleaning performance of the products.

No migration, good stability:

● Good compatibility with polymer carriers, no progressive migration tendency. -

FORNAWAX 3A-740

Overview

● Melting point: 190℃. Used as an additive for processing ultra-high temperature films (such as PI),

● Solving the problem of thermal weight loss of low-temperature processing additives.Brand

FORNAWAX

Model No

3A-740

Industries

Solutions

Application

● Contains amide groups and polarized high carbon chains (better than oleic acid amides and erucic acid amides) ;

● Outstanding smoothness and anti adhesion properties. -

FORNAWAX 3A-735

Overview

● Melting point aT 135℃. Used as an anti-adhesion agent for hightemperature plastic films (TPE/TPU) ;

● Effectively replacing montan wax for both internal and external lubrication.Brand

FORNAWAX

Model No

3A-735

Industries

Solutions

Application

● Contains amide groups and polarized high carbon chains (better than oleic acid amides and erucic acid amides);

● Outstanding smoothness and anti-adhesion properties.

● Reducing friction coefficient to below 0.2. -

FORNAWAX 3E-402

Overview

PC/ABS AlloysBrand

FORNAWAX

Model No

3E-402

Industries

Solutions

Application

● As an interface compatibilizer with strong polarity;

● it is used for PC/ABS alloy to enhance compatibility and reduce the risk of forming stress cracking. -

FORNAWAX 3M-501

Overview

Enhance the interfacial bonding between nylon PA66 and fiberglassBrand

FORNAWAX

Model No

3M-501

Industries

Solutions

Application

● High grafting rate; a compatibilizer withh strong – polarity interface;

● High acid value and is specifically designed to enhance the interfacial bonding between nylon PA66 and fiberglass;

● Effectively reducing the occurance of floating fibers. -

FORNAWAX 3V-203

Overview

Perfect for dispersion in carbon black systemBrand

FORNAWAX

Model No

3V-203

Industries

Solutions

Application

● Offers effective dispersion and lubricity.

● Enhances filler compatibility

● Provides excellent impact resistance and thermal sealability.

● Exhibits excellent resistance to light, water, and corrosion.

● Significantly enhances processing efficiency

● Contains functional groups; and a strong – polarity interface compatibilizer -

FORNAWAX AC-2220

Overview

Excellent internal and external lubrication; good dispersionBrand

FORNAWAX

Model No

AC-2220

Industries

Solutions

Application

● Polyolefins such as PE, PP

● PVC processing lubricant

● Filler

● Predispersed pigment

● Masterbatch -

FORNAWAX XV-203

Overview

Brand

FORNAWAX

Model No

XV-203

Industries

Solutions

Application

• Effective dispersion and lubricity

• Enhance filler compatibility

• Excellent impact resistance and thermal sealability

• Excellent light resistance, water resistance, corrosion resistance

• Significantly enhance production process efficiencySpecifications

Item Unit Typical Value / Properties Softening Point °C 101-107 Viscosity @140°C mPa·s 400-500 Hardness @25° 10-1mm ~3.0 Penetration 10-1mm <6 Density g/cm3 0.92 Acid Value mgKOH/g 13 Appearance White Powder -

FORNAWAX XS-320

Overview

Brand

FORNAWAX

Model No

XS-320

Industries

Solutions

Application

• Increase the loading capacity of pigments and fillers

• Significantly enhance the melt flow properties and increase the melt flow index

• Mitigate filament breakage and fiber strength reduction caused by pigment agglomeration during spinning; Reduce agglomeration formation and prevent re-agglomeration of fillers and pigments

• Improve the compatibility between fillers and matrix resin, enhancing the toughness of modified polymers

• Enhances the surface appearance and processing performance of modified polymers

• Improves production efficiency and molding yield rate

• Excellent thermal stabilitySpecifications

Item Unit Typical Value / Properties Dropping Point °C 130 Stacking Density kg/m3 0.5-0.6 Acid Value mgKOH/g 22 Appearance White Powder -

FORNAWAX XS-310

Overview

Brand

FORNAWAX

Model No

XS-310

Industries

Solutions

Application

• Increase the loading capacity of pigments and fillers

• Significantly enhance the melt flow properties and increase the melt flow index

• Mitigate filament breakage and fiber strength reduction caused by pigment agglomeration during spinning; Reduce agglomeration formation and prevent re-agglomeration of fillers and pigments

• Improve the compatibility between fillers and matrix resin, enhancing the toughness of modified polymers

• Enhances the surface appearance and processing performance of modified polymers

• Improves production efficiency and molding yield rate

• Excellent thermal stabilitySpecifications

Item Unit Typical Value / Properties Dropping Point °C 130 Viscosity @150°C mPa·s <1000 Appearance White Powder -

FORNAWAX OL-10

Overview

Brand

FORNAWAX

Model No

OL-10

Industries

Solutions

Application

• The product exhibits higher melting and softening points than natural waxes and other synthetic waxes, with superior hardness compared to most natural waxes.

• Superior heat resistance and thermal stability.

• Excellent compatibility with polar polymers, inorganic compounds, metal compounds, and related

• Superior polishability, self-healing properties, scratch resistance, and durability.Specifications

Item Unit Typical Value / Properties Drop Melting Point °C 101 Viscosity @140°C cps 200 Hardness @25°C 10-1mm 3-6 Density g/cm3 0.93 Acid Value mgKOH/g 14-17 Appearance White Powder -

FORNAWAX OH-24

Overview

Brand

FORNAWAX

Model No

OH-24

Industries

Solutions

Application

• Improve flowability of materials

• Adjust plasticizing time

• Improve product surface gloss

• Excellent dispersant and release agent

• Applied to transparent productsSpecifications

Item Unit Typical Value / Properties Softening Point °C 133 Viscosity @160°C mPa·s 8000-13000 Hardness @25°C 10-1mm ~1.0 Density g/cm3 0.99 Acid Value mgKOH/g 23-28 Appearance White Powder Size mm <1 -

FORNAWAX AC-2450

Overview

Brand

FORNAWAX

Model No

AC-2450

Industries

Solutions

Application

• Improve flowability of materials

• Adjust plasticizing time

• Effective dispersing agent and release agent

• Paraffin crystal nucleator in wax blends such as candlesSpecifications

Item Unit Typical Value / Properties Softening Point °C 107 Viscosity @140°C mPa·s 400-500 Hardness @25°C 10-1mm >3.0 Density g/cm3 0.92 Appearance White Powder -

FORNAWAX AC-2030

Overview

Brand

FORNAWAX

Model No

AC-2030

Industries

Solutions

Application

• Improve flowability of materials

• Adjust plasticizing time

• Improve the dispersion of inorganic substances

• Improve mold release and product surface glossSpecifications

Item Unit Typical Value / Properties Softening Point °C 106-110 Viscosity @140°C mPa·s 20-30 Hardness @25°C 10-1mm ~3.0 Penetration 10-1mm 1.0-3.0 Density g/cm3 0.92 Appearance White Powder

-

FORNAPLUS ACP Series

Overview

Prevents warping and “cupping” during molding, improving product dimensional stability.Brand

FORNAPLUS

Model No

ACP Series

Industries

Solutions

Application

Prevents warping and “cupping” during molding, improving product dimensional stability. -

FORNAPLUS AOE Series

Overview

Extends the lifespan of plastics by enhancing thermal stability and oxidation resistance.Brand

FORNAPLUS

Model No

AOE Series

Industries

Solutions

Application

Extends the lifespan of plastics by enhancing thermal stability and oxidation resistance. -

FORNAPLUS ASC Series

Overview

Reduces surface scratches and improves long-term appearance durability.Brand

FORNAPLUS

Model No

ASC Series

Industries

Solutions

Application

Reduces surface scratches and improves long-term appearance durability. -

FORNAPLUS CP-704

Overview

Enhance the compatibility between inorganic fillers and the resin system.Brand

FORNAPLUS

Model No

CP-704

Industries

Solutions

Application

Enhance the compatibility between inorganic fillers and the resin system. -

FORNAPLUS CP-801

Overview

• Used as a compatibilizer for PE composite materials filled with bamboo powder/fibers.

• Used as an interface modifier for nylon filled with glass fibers and minerals.

• Used as a compatibilizer for nylon or polyolefin systems.Brand

FORNAPLUS

Model No

CP-801

Industries

Solutions

• Used as a compatibilizer for PE composite materials filled with bamboo powder/fibers.

• Used as an interface modifier for nylon filled with glass fibers and minerals.

• Used as a compatibilizer for nylon or polyolefin systems. -

FORNAPLUS CP-802

Overview

• Used as a compatibilizer for PE composite materials filled with bamboo powder/fibers.

• Used as an interface modifier for nylon filled with glass fibers and minerals.

• Used as a compatibilizer for nylon or polyolefin systems.Brand

FORNAPLUS

Model No

CP-802

Industries

Solutions

• Used as a compatibilizer for PE composite materials filled with bamboo powder/fibers.

• Used as an interface modifier for nylon filled with glass fibers and minerals.

• Used as a compatibilizer for nylon or polyolefin systems. -

FORNAPLUS CP-803

Overview

• Improve the compatibility of POE and PET; help dispersion of POE better in PET; and mprove the toughness of PET resin & Enhance the compatibility of nylon and POE.

• Used as a compatibilizer for nylon; improve compatibility of inorganic powder fillers and nylon; effectively prevent fiber floating In fiber-reinforced materials.

• Used as Compatibilizer for nylon/polypropylene alloy materials.Brand

FORNAPLUS

Model No

CP-803

Industries

Solutions

• Improve the compatibility of POE and PET; help dispersion of POE better in PET; and mprove the toughness of PET resin & Enhance the compatibility of nylon and POE.

• Used as a compatibilizer for nylon; improve compatibility of inorganic powder fillers and nylon; effectively prevent fiber floating In fiber-reinforced materials.

• Used as Compatibilizer for nylon/polypropylene alloy materials. -

FORNAPLUS CP-813

Overview

• Used as a compatibilizer for PBT, PC, PET and glass fibers.

• Used as a toughening agent for PBT and PC.

• Used as a compatibilizer for PBT/PC alloys.Brand

FORNAPLUS

Model No

CP-813

Industries

Solutions

• Used as a compatibilizer for PBT, PC, PET and glass fibers.

• Used as a toughening agent for PBT and PC.

• Used as a compatibilizer for PBT/PC alloys. -

FORNAPLUS FLM Series

Overview

Improves the surface feel of plastics, adding silky and soft touch properties.Brand

FORNAPLUS

Model No

FLM Series

Application

Improves the surface feel of plastics, adding silky and soft touch properties. -

FORNAPLUS MAT Series

Overview

Creates matte finishes with low gloss and reduced fingerprint visibility.Brand

FORNAPLUS

Model No

MAT Series

Application

Creates matte finishes with low gloss and reduced fingerprint visibility. -

FORNAPLUS MB-W60VA

Overview

FORNAPLUS™ MB-W60VA is made from best quality TRONOX Rutile Titanium Dioxide as its main raw materials with Ethylene Vinyl Acetate copolymer (EVA) as carrier.

Benefits:

• Excellent colour stability

• Outstanding dispersion

• Good UV durability

• High tint strength with blue tint tone

• Non-dusting

• Non-toxic eco-friendlyBrand

FORNAPLUS

Model No

MB-W60VA

Application

FORNAPLUS™ MB-W60VA is made from best quality TRONOX Rutile Titanium Dioxide as its main raw materials with Ethylene Vinyl Acetate copolymer (EVA) as carrier.

Benefits:

• Excellent colour stability

• Outstanding dispersion

• Good UV durability

• High tint strength with blue tint tone

• Non-dusting

• Non-toxic eco-friendlySpecifications

Item Standard Compositton 60% Titanium Dioxide (TiO2)

40% Ethylene Vinyl Acetate copolymer (EVA)Density ~ 1,75 g/cm³ Appearance White Granules Advised Dosage 5 – 20 phr -

FORNAPLUS MB-W80EP

Overview

FORNAPLUS™ MB-W60VA is made from best quality TRONOX Rutile Titanium Dioxide as its main raw materials with Ethylene Vinyl Acetate copolymer (EVA) as carrier.

Benefits:

• Excellent colour stability

• Outstanding dispersion

• Good UV durability

• High tint strength with blue tint tone

• Non-dusting

• Non-toxic eco-friendlyBrand

FORNAPLUS

Model No

MB-W80EP

Application

FORNAPLUS™ MB-W60VA is made from best quality TRONOX Rutile Titanium Dioxide as its main raw materials with Ethylene Vinyl Acetate copolymer (EVA) as carrier.

Benefits:

• Excellent colour stability

• Outstanding dispersion

• Good UV durability

• High tint strength with blue tint tone

• Non-dusting

• Non-toxic eco-friendlySpecifications

Item Standard Compositton 80% Titanium Dioxide (TiO2)

20% Ethylene Propylene Terpolymer (EPDM)Density ~ 2. 5 g/cm³ Appearance White Granules Advised Dosage 5 – 20 phr -

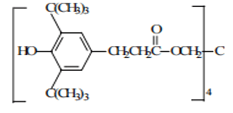

FORNAPLUS OX-1010

Overview

OX-1010, An efficient, non-staining hindered phenolic antioxidant. It can be used in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates.Brand

FORNAPLUS

Model No

OX-1010

Industries

Solutions

Application

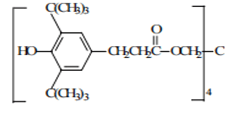

OX-1010, An efficient, non-staining hindered phenolic antioxidant. It can be used in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates.Chemical Name

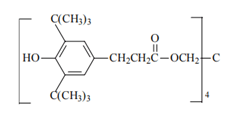

Pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate)

Specifications

Item Typical Value / Properties Molecular Weight 1178 g/mol Melting Point ℃ 110-125℃ Product Forms White free-flowing powder Packing Specification 25 kg/bag -

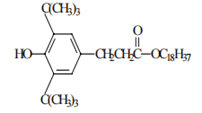

FORNAPLUS OX-1076

Overview

OX-1076, An efficient, non-staining hindered phenolic antioxidant. Suitable for use in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates. Odorless, light-stable, and resistant to discoloration. It exhibits excellent compatibility with substrates, low volatility, and superior resistance to leaching.Brand

FORNAPLUS

Model No

OX-1076

Application

OX-1076, An efficient, non-staining hindered phenolic antioxidant. Suitable for use in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates. Odorless, light-stable, and resistant to discoloration. It exhibits excellent compatibility with substrates, low volatility, and superior resistance to leaching.Chemical Name

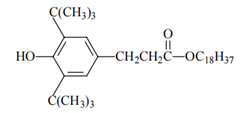

Octadecyl-[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]

Specifications

Item Typical Value / Properties Molecular Weight 530.86 g/mol Melting Point ℃ 50-55℃ Product Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-1098

Overview

OX-1098, A highly efficient, non-discoloring hindered phenolic antioxidant, suitable for various organic substrates such as plastics, synthetic fibers, adhesives, and elastomers, with particular efficacy in polyamide plastics and fibers.Brand

FORNAPLUS

Model No

OX-1098

Industries

Solutions

Application

OX-1098, A highly efficient, non-discoloring hindered phenolic antioxidant, suitable for various organic substrates such as plastics, synthetic fibers, adhesives, and elastomers, with particular efficacy in polyamide plastics and fibers.Chemical Name

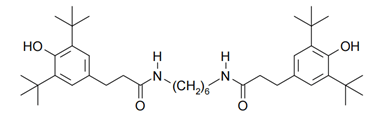

N, N’-hexane-1,6-diylbis(3-(3,5-di-tert.-butyl-4-hydroxyphenylpropionamide))

Specifications

Item Typical Value / Properties Molecular Weight 637 g/mol Melting Point ℃ 156-161℃ Product Forms White free-flowing powder Packing Specification 25 kg/bag -

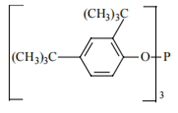

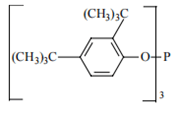

FORNAPLUS OX-168

Overview

OX-168, a processing stabilizer for hydrolysis-resistant phosphites. As a secondary antioxidant, it can react with hydrogen peroxide produced by polymer oxidation during processing to prevent polymer degradation and prolong the antioxidant properties of the primary antioxidant.Brand

FORNAPLUS

Model No

OX-168

Industries

Solutions

Application

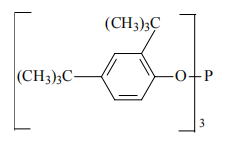

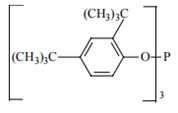

OX-168, a processing stabilizer for hydrolysis-resistant phosphites. As a secondary antioxidant, it can react with hydrogen peroxide produced by polymer oxidation during processing to prevent polymer degradation and prolong the antioxidant properties of the primary antioxidant.Chemical Name

Tris(2,4-ditert-butylphenyl)phosphite

Specifications

Item Typical Value / Properties Molecular Weight 646.9 g/mol Melting Point ℃ 183-186℃ Product Forms White free-flowing powder Packing Specification 25kg/bag -

FORNAPLUS OX-245

Overview

OX-245, A highly efficient hindered phenolic antioxidant, extensively used in various polymers, synthetic fibers, elastomers, adhesives, waxes, oils, and fat-based products to effectively prevent thermal and oxidative degradation of these materials.Brand

FORNAPLUS

Model No

OX-245

Industries

Solutions

Application

OX-245, A highly efficient hindered phenolic antioxidant, extensively used in various polymers, synthetic fibers, elastomers, adhesives, waxes, oils, and fat-based products to effectively prevent thermal and oxidative degradation of these materials.Chemical Name

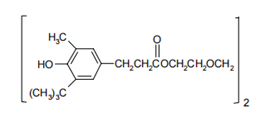

Ethylene bis(oxyethylene) bis-(3-(5-tert-butyl-4-hydroxy-m-tolyl)propionate)

Specifications

Item Typical Value / Properties Molecular Weight 586.8g/mol Melting Point ℃ 76-79℃ Product Forms White free-flowing powder Packing Specification 20kg/bag -

FORNAPLUS OX-B215

Overview

OX-B215, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Brand

FORNAPLUS

Model No

OX-B215

Industries

Solutions

Application

OX-B215, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Chemical Name

33% OX-1010, 67% OX-168

Specifications

Item Typical Value / Properties Molecular Weight OX-1010: 1177.7 g/mol

OX-168: 646.9 g/molProduct Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-B225

Overview

OX-B225, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Brand

FORNAPLUS

Model No

OX-B225

Industries

Solutions

Application

OX-B225, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Chemical Name

50% OX-1010, 50% OX-168

Specifications

Item Typical Value / Properties Molecular Weight OX-1010: 1177.7 g/mol

OX-168: 646.9 g/molProduct Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-B900

Overview

OX-B900, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1076 and OX-168.Brand

FORNAPLUS

Model No

OX-B900

Industries

Solutions

Application

OX-B900, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1076 and OX-168.Chemical Name

20% OX-1076, 80% OX-168

Specifications

Item Typical Value / Properties Molecular Weight OX-1076: 530.86 g/mol

OX-168: 646.9 g/molProduct Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS PES Series

Overview

Adds high-gloss, pearlescent effects for enhanced visual appeal and product differentiation.Brand

FORNAPLUS

Model No

PES Series

Application

Adds high-gloss, pearlescent effects for enhanced visual appeal and product differentiation. -

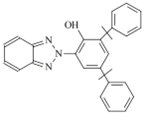

FORNAPLUS UV-234

Overview

UV-234, a high molecular weight phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for many polymers.Brand

FORNAPLUS

Model No

UV-234

Industries

Solutions

Application

UV-234, a high molecular weight phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for many polymers.Chemical Name

Phenol, 2-(2H-benzotriazol-2-yl)-4,6-bis(1-methyl-1-phenylethyl) grade

Specifications

Item Typical Value / Properties Molecular Weight 447.6 g/mol Melting Point ℃ 137-141℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

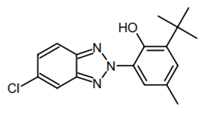

FORNAPLUS UV-326

Overview

UV-326, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substrates.Brand

FORNAPLUS

Model No

UV-326

Industries

Solutions

Application

UV-326, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substrates.Chemical Name

Phenol, 2-(5-chloro-2H-benzotriazol-2-yl)-6-(1,1-dimethylethyl)-4-methyl

Specifications

Item Typical Value / Properties Molecular Weight 315.8 g/mol Melting Point ℃ 138-141℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

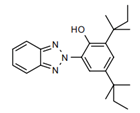

FORNAPLUS UV-328

Overview

UV-328, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substrates.Brand

FORNAPLUS

Model No

UV-328

Industries

Solutions

Application

UV-328, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substrates.Chemical Name

2-(2H-benzotriazol-2-yl)-4, 6-ditertpentylphenol

Specifications

Item Typical Value / Properties Molecular Weight 351.5 g/mol Melting Point ℃ 80-88℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

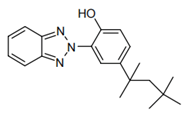

FORNAPLUS UV-329

Overview

UV-329, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substratesBrand

FORNAPLUS

Model No

UV-329

Industries

Solutions

Application

UV-329, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substratesChemical Name

2Phenol, 2-(2H-benzotriazol-2-yl)-4-(1,1,3,3-tetramethylbutyl)

Specifications

Item Typical Value / Properties Molecular Weight 323 g/mol Melting Point ℃ 103-105℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

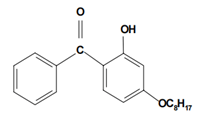

FORNAPLUS UV-531

Overview

UV-531, A benzophenone UV absorbers, when used in combination with hindered amine light stabilizers, can provide good light stabilization protection. Good compatibility with polyolefins and soft PVC.Brand

FORNAPLUS

Model No

UV-531

Industries

Solutions

Application

UV-531, A benzophenone UV absorbers, when used in combination with hindered amine light stabilizers, can provide good light stabilization protection. Good compatibility with polyolefins and soft PVC.Chemical Name

Methanone, [2-hydroxy-4-(octyloxy)phenyl] phenyl, –

Specifications

Item Typical Value / Properties Molecular Weight 326.4 g/mol Melting Point ℃ 48-49℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

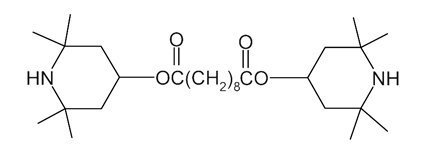

FORNAPLUS UV-770

Overview

FORNAPLUS® UV-770 is a hindered amine light stabilizer (HALS) for applicattons demanding

parttcularly high light stability. It provides excellent light stability for thick secttons but can also be used for artt-cles with a high surface area such as fflms and tapes.Brand

FORNAPLUS

Model No

UV-770

Industries

Solutions

Application

FORNAPLUS® UV-770 is a hindered amine light stabilizer (HALS) for applicattons demanding

parttcularly high light stability. It provides excellent light stability for thick secttons but can also be used for artt-cles with a high surface area such as fflms and tapes.Chemical Name

Bis(2,2,6,6,-tetramethyl-4-piperidyl)sebaceate

Specifications

Item Typical Value / Properties Molecular Weight 481 g/mol Melting Point ℃ 81-85℃ Product Forms 白色结晶颗粒 Packing Specification 20kg/bag -

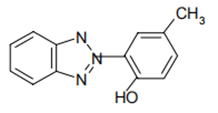

FORNAPLUS UV-P

Overview

UV-P, A phenolic substituted benzotriazole UV absorber that provides good light stabilization for a wide range of resins.Brand

FORNAPLUS

Model No

UV-P

Industries

Solutions

Application

UV-P, A phenolic substituted benzotriazole UV absorber that provides good light stabilization for a wide range of resins.Chemical Name

2-(2-Hydroxy-5-methyl-phenyl)-2H-benzotriazole

Specifications

Item Typical Value / Properties Molecular Weight 225 g/mol Melting Point ℃ 128-132℃ Product Forms Pale yellow powder Packing Specification 20kg/bag

Laboratory Hub

At FORNAX’s headquarters in Leverkusen, scientists conduct in-depth research on molecular structures and dispersion efficiency, ensuring product stability and high performance.

Smart Manufacturing Facility

At FORNAX’s European facility, smart automation and digital monitoring ensure efficient and consistent production. Engineers rely on real-time data to guarantee strict quality control.

Industrial Base

Headquartered in Leverkusen, Germany, FORNAX benefits from being at the heart of Europe’s chemical manufacturing hub — surrounded by world-class industrial infrastructure and innovation networks.

Open-Pit Mine in Brazil

This expansive open-pit mine, nestled in a Brazilian valley, exemplifies the scale and efficiency of raw material sourcing. With heavy equipment in action and intricate logistics routes, it reflects the operational strength behind FORNAX’s supply chain.

Mining Team in Australia

Workers in full protective gear walk through an active mining site in Australia, highlighting the disciplined field operations and safety-first culture. Australia plays a pivotal role in the global sourcing of titanium raw materials for FORNAX.