Industry: Engineering Plastics

Engineering plastics are specialized materials designed for high-performance applications in demanding industrial sectors. These plastics offer enhanced mechanical strength, thermal stability, and chemical resistance, maintaining consistent performance even in harsh environments. Below is our curated selection of products for engineering plastics applications, featuring FORNAWAX®, FORNAPLUS®, TIONA®, TIKON®, and FORMOSA®, all aimed at improving processing performance, stability, and durability to meet the needs of diverse industries.

-

FORNAWAX XS-326

Overview

Modified Polysiloxane Processing Aid

A modified polysiloxane product after surface treatment for:

● Polyolefins such as PE, PP

● Functional polymers such as PA6, PA66

● Filling base materials

● Industrial polymers

● MasterbatchesBrand

FORNAWAX

Model No

XS-326

Industries

Solutions

Application

A modified polysiloxane product after surface treatment for:

● Polyolefins such as PE, PP

● Functional polymers such as PA6, PA66

● Filling base materials

● Industrial polymers

● Masterbatches -

FORNAWAX XS-350

Overview

Modified Silicone Processing Aid

As organic silicon plastic processing aid with polarized groups at both ends; and as lubricatiing and dispersing agents for pigments and fillers:

● Polyolefins such as PE, PP

● Functional polymers such as PA6, PA66

● Filling base materials

● Industrial polymers

● MasterbatchesBrand

FORNAWAX

Model No

XS-350

Industries

Solutions

Application

As organic silicon plastic processing aid with polarized groups at both ends; and as lubricatiing and dispersing agents for pigments and fillers:

● Polyolefins such as PE, PP

● Functional polymers such as PA6, PA66

● Filling base materials

● Industrial polymers

● Masterbatches -

FORNAWAX 3A-740

Overview

Amide Wax

● Melting point: 190℃. Used as an additive for processing ultra-high temperature films (such as PI),

● Solving the problem of thermal weight loss of low-temperature processing additives.Brand

FORNAWAX

Model No

3A-740

Industries

Solutions

Application

● Melting point: 190℃. Used as an additive for processing ultra-high temperature films (such as PI),

● Solving the problem of thermal weight loss of low-temperature processing additives. -

FORNAWAX 3A-735

Overview

Amide Wax

● Melting point aT 135℃. Used as an anti-adhesion agent for hightemperature plastic films (TPE/TPU) ;

● Effectively replacing montan wax for both internal and external lubrication.Brand

FORNAWAX

Model No

3A-735

Industries

Solutions

Application

● Melting point aT 135℃. Used as an anti-adhesion agent for hightemperature plastic films (TPE/TPU) ;

● Effectively replacing montan wax for both internal and external lubrication. -

FORNAWAX 3E-402

Overview

Ethylene-Acrylate Copolymer Grafted Wax

PC/ABS AlloysBrand

FORNAWAX

Model No

3E-402

Industries

Solutions

Application

PC/ABS Alloys -

FORNAWAX 3M-501

Overview

Polyethylene Wax Grafted with Maleic Anhydride (MAH)

Enhance the interfacial bonding between nylon PA66 and fiberglassBrand

FORNAWAX

Model No

3M-501

Industries

Solutions

Application

Enhance the interfacial bonding between nylon PA66 and fiberglass -

FORNAWAX 3V-203

Overview

Low Molecular Weight Ethylene-vinyl Acetate Copolymer Grafted Wax

Perfect for dispersion in carbon black systemBrand

FORNAWAX

Model No

3V-203

Industries

Solutions

Application

Perfect for dispersion in carbon black system -

FORNAWAX AC-2220

Overview

Linear Polyethylene Wax with Medium Viscosity

Excellent internal and external lubrication; good dispersionBrand

FORNAWAX

Model No

AC-2220

Industries

Solutions

Application

Excellent internal and external lubrication; good dispersion -

FORNAWAX XV-203

Overview

Low Molecular Weight Ethylene-vinyl Acetate Copolymer

Brand

FORNAWAX

Model No

XV-203

Industries

Solutions

Application

Specifications

Item Unit Typical Value / Properties Softening Point °C 101-107 Viscosity @140°C mPa·s 400-500 Hardness @25° 10-1mm ~3.0 Penetration 10-1mm <6 Density g/cm3 0.92 Acid Value mgKOH/g 13 Appearance White Powder -

FORNAWAX XS-320

Overview

Highly Amphiphilic Graft Copolymer

Brand

FORNAWAX

Model No

XS-320

Industries

Solutions

Application

Specifications

Item Unit Typical Value / Properties Dropping Point °C 130 Stacking Density kg/m3 0.5-0.6 Acid Value mgKOH/g 22 Appearance White Powder

-

FORNAPLUS UV-770

Overview

UV Absorber

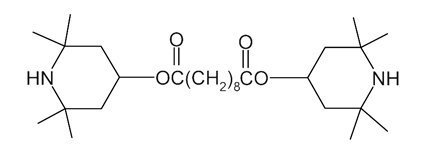

FORNAPLUS® UV-770 is a hindered amine light stabilizer (HALS) for applicattons demanding

parttcularly high light stability. It provides excellent light stability for thick secttons but can also be used for artt-cles with a high surface area such as fflms and tapes.Brand

FORNAPLUS

Model No

UV-770

Industries

Solutions

Application

FORNAPLUS® UV-770 is a hindered amine light stabilizer (HALS) for applicattons demanding

parttcularly high light stability. It provides excellent light stability for thick secttons but can also be used for artt-cles with a high surface area such as fflms and tapes.Chemical Name

Bis(2,2,6,6,-tetramethyl-4-piperidyl)sebaceate

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 481 g/mol Melting Point ℃ 81-85℃ Product Forms 白色结晶颗粒 Packing Specification 20kg/bag -

FORNAPLUS OX-168

Overview

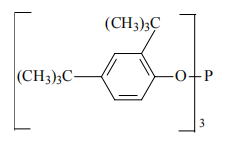

Antioxidant

OX-168, a processing stabilizer for hydrolysis-resistant phosphites. As a secondary antioxidant, it can react with hydrogen peroxide produced by polymer oxidation during processing to prevent polymer degradation and prolong the antioxidant properties of the primary antioxidant.Brand

FORNAPLUS

Model No

OX-168

Industries

Solutions

Application

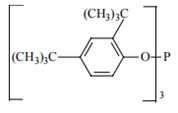

OX-168, a processing stabilizer for hydrolysis-resistant phosphites. As a secondary antioxidant, it can react with hydrogen peroxide produced by polymer oxidation during processing to prevent polymer degradation and prolong the antioxidant properties of the primary antioxidant.Chemical Name

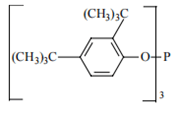

Tris(2,4-ditert-butylphenyl)phosphite

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 646.9 g/mol Melting Point ℃ 183-186℃ Product Forms White free-flowing powder Packing Specification 25kg/bag -

FORNAPLUS MAT Series

Overview

Matting Agents

Creates matte finishes with low gloss and reduced fingerprint visibility.Brand

FORNAPLUS

Model No

MAT Series

Application

Creates matte finishes with low gloss and reduced fingerprint visibility. -

FORNAPLUS ASC Series

Overview

Anti-scratch Agents

Reduces surface scratches and improves long-term appearance durability.Brand

FORNAPLUS

Model No

ASC Series

Industries

Solutions

Application

Reduces surface scratches and improves long-term appearance durability. -

FORNAPLUS PES Series

Overview

Pearlescent Agents

Adds high-gloss, pearlescent effects for enhanced visual appeal and product differentiation.Brand

FORNAPLUS

Model No

PES Series

Application

Adds high-gloss, pearlescent effects for enhanced visual appeal and product differentiation. -

FORNAPLUS ACP Series

Overview

Anti-cup Removal Agents

Prevents warping and “cupping” during molding, improving product dimensional stability.Brand

FORNAPLUS

Model No

ACP Series

Industries

Solutions

Application

Prevents warping and “cupping” during molding, improving product dimensional stability. -

FORNAPLUS AOE Series

Overview

Antioxidant Enhancers

Extends the lifespan of plastics by enhancing thermal stability and oxidation resistance.Brand

FORNAPLUS

Model No

AOE Series

Industries

Solutions

Application

Extends the lifespan of plastics by enhancing thermal stability and oxidation resistance. -

FORNAPLUS FLM Series

Overview

Feel Modifiers

Improves the surface feel of plastics, adding silky and soft touch properties.Brand

FORNAPLUS

Model No

FLM Series

Application

Improves the surface feel of plastics, adding silky and soft touch properties. -

FORNAPLUS CP-813

Overview

Compatibilizer (POE grafted with GMA)

• Used as a compatibilizer for PBT, PC, PET and glass fibers.

• Used as a toughening agent for PBT and PC.

• Used as a compatibilizer for PBT/PC alloys.Brand

FORNAPLUS

Model No

CP-813

Industries

Solutions

• Used as a compatibilizer for PBT, PC, PET and glass fibers.

• Used as a toughening agent for PBT and PC.

• Used as a compatibilizer for PBT/PC alloys. -

FORNAPLUS CP-803

Overview

Compatibilizer (POE grafted with MAH)

• Improve the compatibility of POE and PET; help dispersion of POE better in PET; and mprove the toughness of PET resin & Enhance the compatibility of nylon and POE.

• Used as a compatibilizer for nylon; improve compatibility of inorganic powder fillers and nylon; effectively prevent fiber floating In fiber-reinforced materials.

• Used as Compatibilizer for nylon/polypropylene alloy materials.Brand

FORNAPLUS

Model No

CP-803

Industries

Solutions

• Improve the compatibility of POE and PET; help dispersion of POE better in PET; and mprove the toughness of PET resin & Enhance the compatibility of nylon and POE.

• Used as a compatibilizer for nylon; improve compatibility of inorganic powder fillers and nylon; effectively prevent fiber floating In fiber-reinforced materials.

• Used as Compatibilizer for nylon/polypropylene alloy materials. -

FORNAPLUS CP-802

Overview

Compatibilizer (PE grafted with MAH)

• Used as a compatibilizer for PE composite materials filled with bamboo powder/fibers.

• Used as an interface modifier for nylon filled with glass fibers and minerals.

• Used as a compatibilizer for nylon or polyolefin systems.Brand

FORNAPLUS

Model No

CP-802

Industries

Solutions

• Used as a compatibilizer for PE composite materials filled with bamboo powder/fibers.

• Used as an interface modifier for nylon filled with glass fibers and minerals.

• Used as a compatibilizer for nylon or polyolefin systems. -

FORNAPLUS CP-801

Overview

Compatibilizer (PE grafted with MAH)

• Used as a compatibilizer for PE composite materials filled with bamboo powder/fibers.

• Used as an interface modifier for nylon filled with glass fibers and minerals.

• Used as a compatibilizer for nylon or polyolefin systems.Brand

FORNAPLUS

Model No

CP-801

Industries

Solutions

• Used as a compatibilizer for PE composite materials filled with bamboo powder/fibers.

• Used as an interface modifier for nylon filled with glass fibers and minerals.

• Used as a compatibilizer for nylon or polyolefin systems. -

FORNAPLUS CP-704

Overview

Coupling Agent (Aluminate)

Enhance the compatibility between inorganic fillers and the resin system.Brand

FORNAPLUS

Model No

CP-704

Industries

Solutions

Application

Enhance the compatibility between inorganic fillers and the resin system. -

FORNAPLUS UV-P

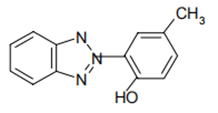

Overview

UV Absorber

UV-P, A phenolic substituted benzotriazole UV absorber that provides good light stabilization for a wide range of resins.Brand

FORNAPLUS

Model No

UV-P

Industries

Solutions

Application

UV-P, A phenolic substituted benzotriazole UV absorber that provides good light stabilization for a wide range of resins.Chemical Name

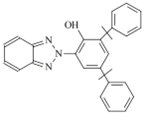

2-(2-Hydroxy-5-methyl-phenyl)-2H-benzotriazole

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 225 g/mol Melting Point ℃ 128-132℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

FORNAPLUS UV-531

Overview

UV Absorber

UV-531, A benzophenone UV absorbers, when used in combination with hindered amine light stabilizers, can provide good light stabilization protection. Good compatibility with polyolefins and soft PVC.Brand

FORNAPLUS

Model No

UV-531

Industries

Solutions

Application

UV-531, A benzophenone UV absorbers, when used in combination with hindered amine light stabilizers, can provide good light stabilization protection. Good compatibility with polyolefins and soft PVC.Chemical Name

Methanone, [2-hydroxy-4-(octyloxy)phenyl] phenyl, –

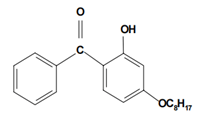

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 326.4 g/mol Melting Point ℃ 48-49℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

FORNAPLUS UV-329

Overview

UV Absorber

UV-329, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substratesBrand

FORNAPLUS

Model No

UV-329

Industries

Solutions

Application

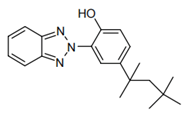

UV-329, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substratesChemical Name

2Phenol, 2-(2H-benzotriazol-2-yl)-4-(1,1,3,3-tetramethylbutyl)

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 323 g/mol Melting Point ℃ 103-105℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

FORNAPLUS UV-328

Overview

UV Absorber

UV-328, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substrates.Brand

FORNAPLUS

Model No

UV-328

Industries

Solutions

Application

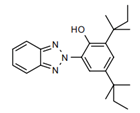

UV-328, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substrates.Chemical Name

2-(2H-benzotriazol-2-yl)-4, 6-ditertpentylphenol

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 351.5 g/mol Melting Point ℃ 80-88℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

FORNAPLUS UV-326

Overview

UV Absorber

UV-326, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substrates.Brand

FORNAPLUS

Model No

UV-326

Industries

Solutions

Application

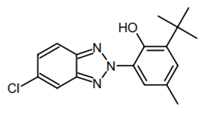

UV-326, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substrates.Chemical Name

Phenol, 2-(5-chloro-2H-benzotriazol-2-yl)-6-(1,1-dimethylethyl)-4-methyl

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 315.8 g/mol Melting Point ℃ 138-141℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

FORNAPLUS OX-B900

Overview

Antioxidant

OX-B900, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1076 and OX-168.Brand

FORNAPLUS

Model No

OX-B900

Industries

Solutions

Application

OX-B900, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1076 and OX-168.Chemical Name

20% OX-1076, 80% OX-168

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight OX-1076: 530.86 g/mol

OX-168: 646.9 g/molProduct Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-B225

Overview

Antioxidant

OX-B225, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Brand

FORNAPLUS

Model No

OX-B225

Industries

Solutions

Application

OX-B225, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Chemical Name

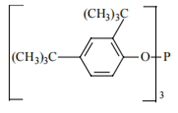

50% OX-1010, 50% OX-168

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight OX-1010: 1177.7 g/mol

OX-168: 646.9 g/molProduct Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-B215

Overview

Antioxidant

OX-B215, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Brand

FORNAPLUS

Model No

OX-B215

Industries

Solutions

Application

OX-B215, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Chemical Name

33% OX-1010, 67% OX-168

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight OX-1010: 1177.7 g/mol

OX-168: 646.9 g/molProduct Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-1098

Overview

Antioxidant

OX-1098, A highly efficient, non-discoloring hindered phenolic antioxidant, suitable for various organic substrates such as plastics, synthetic fibers, adhesives, and elastomers, with particular efficacy in polyamide plastics and fibers.Brand

FORNAPLUS

Model No

OX-1098

Industries

Solutions

Application

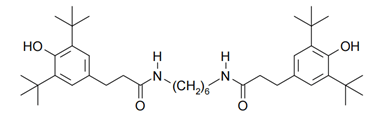

OX-1098, A highly efficient, non-discoloring hindered phenolic antioxidant, suitable for various organic substrates such as plastics, synthetic fibers, adhesives, and elastomers, with particular efficacy in polyamide plastics and fibers.Chemical Name

N, N’-hexane-1,6-diylbis(3-(3,5-di-tert.-butyl-4-hydroxyphenylpropionamide))

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 637 g/mol Melting Point ℃ 156-161℃ Product Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-1076

Overview

Antioxidant

OX-1076, An efficient, non-staining hindered phenolic antioxidant. Suitable for use in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates. Odorless, light-stable, and resistant to discoloration. It exhibits excellent compatibility with substrates, low volatility, and superior resistance to leaching.Brand

FORNAPLUS

Model No

OX-1076

Industries

Solutions

Application

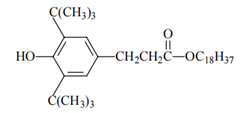

OX-1076, An efficient, non-staining hindered phenolic antioxidant. Suitable for use in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates. Odorless, light-stable, and resistant to discoloration. It exhibits excellent compatibility with substrates, low volatility, and superior resistance to leaching.Chemical Name

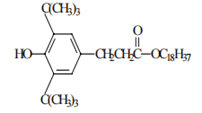

Octadecyl-[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 530.86 g/mol Melting Point ℃ 50-55℃ Product Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-1010

Overview

Antioxidant

OX-1010, An efficient, non-staining hindered phenolic antioxidant. It can be used in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates.Brand

FORNAPLUS

Model No

OX-1010

Industries

Solutions

Application

OX-1010, An efficient, non-staining hindered phenolic antioxidant. It can be used in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates.Chemical Name

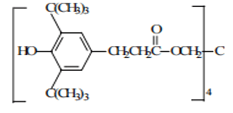

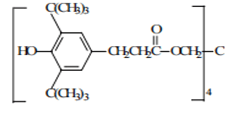

Pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate)

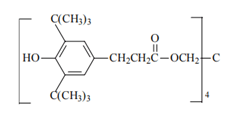

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 1178 g/mol Melting Point ℃ 110-125℃ Product Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-245

Overview

Antioxidant

OX-245, A highly efficient hindered phenolic antioxidant, extensively used in various polymers, synthetic fibers, elastomers, adhesives, waxes, oils, and fat-based products to effectively prevent thermal and oxidative degradation of these materials.Brand

FORNAPLUS

Model No

OX-245

Industries

Solutions

Application

OX-245, A highly efficient hindered phenolic antioxidant, extensively used in various polymers, synthetic fibers, elastomers, adhesives, waxes, oils, and fat-based products to effectively prevent thermal and oxidative degradation of these materials.Chemical Name

Ethylene bis(oxyethylene) bis-(3-(5-tert-butyl-4-hydroxy-m-tolyl)propionate)

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 586.8g/mol Melting Point ℃ 76-79℃ Product Forms White free-flowing powder Packing Specification 20kg/bag -

FORNAPLUS UV-234

Overview

UV Absorber

UV-234, a high molecular weight phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for many polymers.Brand

FORNAPLUS

Model No

UV-234

Industries

Solutions

Application

UV-234, a high molecular weight phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for many polymers.Chemical Name

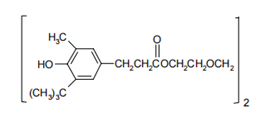

Phenol, 2-(2H-benzotriazol-2-yl)-4,6-bis(1-methyl-1-phenylethyl) grade

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 447.6 g/mol Melting Point ℃ 137-141℃ Product Forms Pale yellow powder Packing Specification 20kg/bag

-

TiONA TPD-103

Overview

White Pigment

TPD-103 is a high performance blue undertone, rutile titanium dioxide pigment, manufactured by the advanced chloride process. It is specifically designed for compounding Polycarbonate and

Polycarbonate alloys. Its surface treatment has been optimised to provide the highest level of optical performance, thermal stability and retention of physical properties.

Key Features:

• Excellent thermal stability

• Outstanding brightness and whiteness

• Excellent dispersion & retention of physical properties

• Good processability

• High tint strength with blue tint toneBrand

TiONA

Model No

TPD-103

Application

TPD-103 is a high performance blue undertone, rutile titanium dioxide pigment, manufactured by the advanced chloride process. It is specifically designed for compounding Polycarbonate and

Polycarbonate alloys. Its surface treatment has been optimised to provide the highest level of optical performance, thermal stability and retention of physical properties.

Key Features:

• Excellent thermal stability

• Outstanding brightness and whiteness

• Excellent dispersion & retention of physical properties

• Good processability

• High tint strength with blue tint toneChemical Name

Titanium Dioxide

-

TiONA RCL-69

Overview

White Pigment

TiONA® RCL-69 is a blue tint tone, chloride-process rutile titanium dioxide pigment, designed to provide excellent optical performance and dispersibility in a wide range of plastics. It is particularly recommended for for use in polyolefin masterbatch and with many polymers and compounds where durability is not required.

Key Features:

• Outstanding brightness and whiteness

• Blue tint tone

• Excellent dispersibility

• Excellent processability

• Excellent powder handling

• HydrophobicBrand

TiONA

Model No

RCL-69

Industries

Solutions

Application

TiONA® RCL-69 is a blue tint tone, chloride-process rutile titanium dioxide pigment, designed to provide excellent optical performance and dispersibility in a wide range of plastics. It is particularly recommended for for use in polyolefin masterbatch and with many polymers and compounds where durability is not required.

Key Features:

• Outstanding brightness and whiteness

• Blue tint tone

• Excellent dispersibility

• Excellent processability

• Excellent powder handling

• HydrophobicChemical Name

Titanium Dioxide

-

TiONA 288

Overview

White Pigment

TiONA® 288 is a blue tint tone, rutile titanium dioxide pigment, manufactured by the advanced chloride process. It has been designed for use in high performance white and tinted polyolefin masterbatch and compounds. The surface treatment provides the optimum combination of high temperature performance with optical efficiency, high pigment loading and ease of dispersion. This ensures TiONA® 288 has excellent processability, making it particularly suitable for high-temperature and dispersion critical film applications.Brand

TiONA

Model No

288

Industries

Solutions

Application

TiONA® 288 is a blue tint tone, rutile titanium dioxide pigment, manufactured by the advanced chloride process. It has been designed for use in high performance white and tinted polyolefin masterbatch and compounds. The surface treatment provides the optimum combination of high temperature performance with optical efficiency, high pigment loading and ease of dispersion. This ensures TiONA® 288 has excellent processability, making it particularly suitable for high-temperature and dispersion critical film applications.Chemical Name

Titanium Dioxide

-

TiONA 233

Overview

White Pigment

TiONA® 233 is a blue tint tone, rutile titanium dioxide pigment, manufactured by the advanced chloride process. Its surface treatment has been optimized to provide the ultimate combination of optical efficiency, dispersion and processing performance along with excellent colour stability/resistance to UV. It is particularly suited for producing highly loaded masterbatches and critical thin films requiring durability.

Key Features:

• Excellent colour stability

• Outstanding dispersion

• Outstanding brightness and cleanliness of mass tone

• Good UV resistance

• Good high temperature processing

• High tint strength with blue tint tone

• HydrophobicBrand

TiONA

Model No

233

Industries

Solutions

Application

TiONA® 233 is a blue tint tone, rutile titanium dioxide pigment, manufactured by the advanced chloride process. Its surface treatment has been optimized to provide the ultimate combination of optical efficiency, dispersion and processing performance along with excellent colour stability/resistance to UV. It is particularly suited for producing highly loaded masterbatches and critical thin films requiring durability.

Key Features:

• Excellent colour stability

• Outstanding dispersion

• Outstanding brightness and cleanliness of mass tone

• Good UV resistance

• Good high temperature processing

• High tint strength with blue tint tone

• HydrophobicChemical Name

Titanium Dioxide

-

TiKON 36

Overview

White Pigment

TiKON™ 36 is a bluish tint tone, sulfate-process, rutile titanium dioxide pigment, designed to provide good optical performance and dispersibility in a wide range of plastics.Brand

TIKON

Model No

36

Industries

Solutions

Application

TiKON™ 36 is a bluish tint tone, sulfate-process, rutile titanium dioxide pigment, designed to provide good optical performance and dispersibility in a wide range of plastics.Chemical Name

Titanium Dioxide

-

FORMOSA K-210

Overview

PVC Impact Modifier

Silicone rubber/acrylate co-polymer FORMOLON K-210 is used for general plastics and engineering plastics. According to well dispersion in resin, it can improve impact strength, surface appearance, help obtain excellent weathering resistance, good processing performance and high productivity, etc.Brand

FORMOSA

Model No

K-210

Application

Silicone rubber/acrylate co-polymer FORMOLON K-210 is used for general plastics and engineering plastics. According to well dispersion in resin, it can improve impact strength, surface appearance, help obtain excellent weathering resistance, good processing performance and high productivity, etc.Specifications

Appearance White Bulk Density (g/cm³) 0.36 min Volatility (%) 1.0 max Foreign Particles (PC/100g) 30 Max Particle Size on 16 mesh sieve (%) 1.0 Max Notched IZOD Impact

(23℃ at Dosage 4% (Kg-cm/cm)40 min Notched IZOD Impact

(-15C at Dosage 4% (Kg-cm/cm)MI

Melt Flow Index (240 ℃ @ 5 kg, 4% addition) (g/10 min) -

FORMOSA P-201

Overview

Processing Aid

General plasticization. Can be use in PVC system.Brand

FORMOSA

Model No

P-201

Application

General plasticization. Can be use in PVC system.Specifications

Appearance White Powder Bulk Density (g/cm³) 0.40 max Volatility (%) 1.0 max Average Particle Size(μm) 100-130 Particle Size(+60 /- 325mesh) 1% / 3%