Industry: PVC Products & Stabilizers

PVC Products & Stabilizers are essential materials used across various industries such as construction, automotive, and electronics. PVC offers excellent durability, UV resistance, and chemical stability, while stabilizers enhance its thermal stability and aging resistance. Our range of products from FORNAWAX, FORNAPLUS, TIONA, TIKON, FORMOSA, and NAN YA is designed for the processing and stabilization of PVC products, helping to improve product quality and extend service life for diverse industrial applications.

-

FORNAWAX XS-326

Overview

Modified Polysiloxane Processing Aid

A modified polysiloxane product after surface treatment for:

● Polyolefins such as PE, PP

● Functional polymers such as PA6, PA66

● Filling base materials

● Industrial polymers

● MasterbatchesBrand

FORNAWAX

Model No

XS-326

Industries

Solutions

Application

A modified polysiloxane product after surface treatment for:

● Polyolefins such as PE, PP

● Functional polymers such as PA6, PA66

● Filling base materials

● Industrial polymers

● Masterbatches -

FORNAWAX XS-350

Overview

Modified Silicone Processing Aid

As organic silicon plastic processing aid with polarized groups at both ends; and as lubricatiing and dispersing agents for pigments and fillers:

● Polyolefins such as PE, PP

● Functional polymers such as PA6, PA66

● Filling base materials

● Industrial polymers

● MasterbatchesBrand

FORNAWAX

Model No

XS-350

Industries

Solutions

Application

As organic silicon plastic processing aid with polarized groups at both ends; and as lubricatiing and dispersing agents for pigments and fillers:

● Polyolefins such as PE, PP

● Functional polymers such as PA6, PA66

● Filling base materials

● Industrial polymers

● Masterbatches -

FORNAWAX AC-2220

Overview

Linear Polyethylene Wax with Medium Viscosity

Excellent internal and external lubrication; good dispersionBrand

FORNAWAX

Model No

AC-2220

Industries

Solutions

Application

Excellent internal and external lubrication; good dispersion -

FORNAWAX XS-310

Overview

Highly Amphiphilic Copoly

Brand

FORNAWAX

Model No

XS-310

Industries

Solutions

Application

Chemical Structure

Specifications

Item Unit Typical Value / Properties Dropping Point °C 130 Viscosity @150°C mPa·s <1000 Appearance White Powder -

FORNAWAX OL-10

Overview

Oxidized Polyethylene Homopolymer

Brand

FORNAWAX

Model No

OL-10

Industries

Solutions

Application

Specifications

Item Unit Typical Value / Properties Drop Melting Point °C 101 Viscosity @140°C cps 200 Hardness @25°C 10-1mm 3-6 Density g/cm3 0.93 Acid Value mgKOH/g 14-17 Appearance White Powder -

FORNAWAX OH-24

Overview

Low Molecular Weight Oxidized Polyethylene Wax

Brand

FORNAWAX

Model No

OH-24

Industries

Solutions

Application

Specifications

Item Unit Typical Value / Properties Softening Point °C 133 Viscosity @160°C mPa·s 8000-13000 Hardness @25°C 10-1mm ~1.0 Density g/cm3 0.99 Acid Value mgKOH/g 23-28 Appearance White Powder Size mm <1 -

FORNAWAX AC-2450

Overview

Low Molecular Weight Polyethylene Wax

Brand

FORNAWAX

Model No

AC-2450

Industries

Solutions

Application

Specifications

Item Unit Typical Value / Properties Softening Point °C 107 Viscosity @140°C mPa·s 400-500 Hardness @25°C 10-1mm >3.0 Density g/cm3 0.92 Appearance White Powder -

FORNAWAX AC-2030

Overview

Low Molecular Weight Polyethylene Wax

Brand

FORNAWAX

Model No

AC-2030

Industries

Solutions

Application

Specifications

Item Unit Typical Value / Properties Softening Point °C 106-110 Viscosity @140°C mPa·s 20-30 Hardness @25°C 10-1mm ~3.0 Penetration 10-1mm 1.0-3.0 Density g/cm3 0.92 Appearance White Powder

-

FORNAPLUS UV-770

Overview

UV Absorber

FORNAPLUS® UV-770 is a hindered amine light stabilizer (HALS) for applicattons demanding

parttcularly high light stability. It provides excellent light stability for thick secttons but can also be used for artt-cles with a high surface area such as fflms and tapes.Brand

FORNAPLUS

Model No

UV-770

Industries

Solutions

Application

FORNAPLUS® UV-770 is a hindered amine light stabilizer (HALS) for applicattons demanding

parttcularly high light stability. It provides excellent light stability for thick secttons but can also be used for artt-cles with a high surface area such as fflms and tapes.Chemical Name

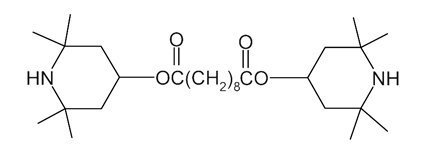

Bis(2,2,6,6,-tetramethyl-4-piperidyl)sebaceate

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 481 g/mol Melting Point ℃ 81-85℃ Product Forms 白色结晶颗粒 Packing Specification 20kg/bag -

FORNAPLUS OX-168

Overview

Antioxidant

OX-168, a processing stabilizer for hydrolysis-resistant phosphites. As a secondary antioxidant, it can react with hydrogen peroxide produced by polymer oxidation during processing to prevent polymer degradation and prolong the antioxidant properties of the primary antioxidant.Brand

FORNAPLUS

Model No

OX-168

Industries

Solutions

Application

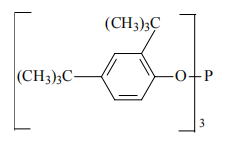

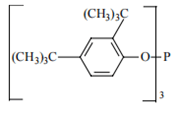

OX-168, a processing stabilizer for hydrolysis-resistant phosphites. As a secondary antioxidant, it can react with hydrogen peroxide produced by polymer oxidation during processing to prevent polymer degradation and prolong the antioxidant properties of the primary antioxidant.Chemical Name

Tris(2,4-ditert-butylphenyl)phosphite

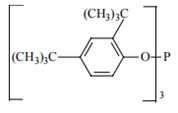

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 646.9 g/mol Melting Point ℃ 183-186℃ Product Forms White free-flowing powder Packing Specification 25kg/bag -

FORNAPLUS CP-704

Overview

Coupling Agent (Aluminate)

Enhance the compatibility between inorganic fillers and the resin system.Brand

FORNAPLUS

Model No

CP-704

Industries

Solutions

Application

Enhance the compatibility between inorganic fillers and the resin system. -

FORNAPLUS UV-P

Overview

UV Absorber

UV-P, A phenolic substituted benzotriazole UV absorber that provides good light stabilization for a wide range of resins.Brand

FORNAPLUS

Model No

UV-P

Industries

Solutions

Application

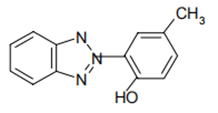

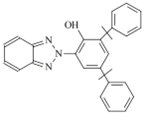

UV-P, A phenolic substituted benzotriazole UV absorber that provides good light stabilization for a wide range of resins.Chemical Name

2-(2-Hydroxy-5-methyl-phenyl)-2H-benzotriazole

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 225 g/mol Melting Point ℃ 128-132℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

FORNAPLUS UV-531

Overview

UV Absorber

UV-531, A benzophenone UV absorbers, when used in combination with hindered amine light stabilizers, can provide good light stabilization protection. Good compatibility with polyolefins and soft PVC.Brand

FORNAPLUS

Model No

UV-531

Industries

Solutions

Application

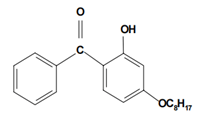

UV-531, A benzophenone UV absorbers, when used in combination with hindered amine light stabilizers, can provide good light stabilization protection. Good compatibility with polyolefins and soft PVC.Chemical Name

Methanone, [2-hydroxy-4-(octyloxy)phenyl] phenyl, –

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 326.4 g/mol Melting Point ℃ 48-49℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

FORNAPLUS UV-329

Overview

UV Absorber

UV-329, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substratesBrand

FORNAPLUS

Model No

UV-329

Industries

Solutions

Application

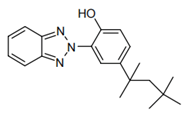

UV-329, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substratesChemical Name

2Phenol, 2-(2H-benzotriazol-2-yl)-4-(1,1,3,3-tetramethylbutyl)

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 323 g/mol Melting Point ℃ 103-105℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

FORNAPLUS UV-328

Overview

UV Absorber

UV-328, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substrates.Brand

FORNAPLUS

Model No

UV-328

Industries

Solutions

Application

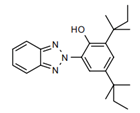

UV-328, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substrates.Chemical Name

2-(2H-benzotriazol-2-yl)-4, 6-ditertpentylphenol

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 351.5 g/mol Melting Point ℃ 80-88℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

FORNAPLUS UV-326

Overview

UV Absorber

UV-326, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substrates.Brand

FORNAPLUS

Model No

UV-326

Industries

Solutions

Application

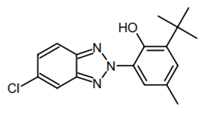

UV-326, a phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for plastics and other organic substrates.Chemical Name

Phenol, 2-(5-chloro-2H-benzotriazol-2-yl)-6-(1,1-dimethylethyl)-4-methyl

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 315.8 g/mol Melting Point ℃ 138-141℃ Product Forms Pale yellow powder Packing Specification 20kg/bag -

FORNAPLUS OX-B900

Overview

Antioxidant

OX-B900, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1076 and OX-168.Brand

FORNAPLUS

Model No

OX-B900

Industries

Solutions

Application

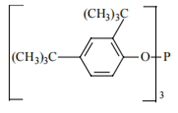

OX-B900, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1076 and OX-168.Chemical Name

20% OX-1076, 80% OX-168

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight OX-1076: 530.86 g/mol

OX-168: 646.9 g/molProduct Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-B225

Overview

Antioxidant

OX-B225, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Brand

FORNAPLUS

Model No

OX-B225

Industries

Solutions

Application

OX-B225, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Chemical Name

50% OX-1010, 50% OX-168

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight OX-1010: 1177.7 g/mol

OX-168: 646.9 g/molProduct Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-B215

Overview

Antioxidant

OX-B215, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Brand

FORNAPLUS

Model No

OX-B215

Industries

Solutions

Application

OX-B215, A synergistic processing/long-term thermal stabilizer formulated from a blend of OX-1010 and OX-168.Chemical Name

33% OX-1010, 67% OX-168

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight OX-1010: 1177.7 g/mol

OX-168: 646.9 g/molProduct Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-1098

Overview

Antioxidant

OX-1098, A highly efficient, non-discoloring hindered phenolic antioxidant, suitable for various organic substrates such as plastics, synthetic fibers, adhesives, and elastomers, with particular efficacy in polyamide plastics and fibers.Brand

FORNAPLUS

Model No

OX-1098

Industries

Solutions

Application

OX-1098, A highly efficient, non-discoloring hindered phenolic antioxidant, suitable for various organic substrates such as plastics, synthetic fibers, adhesives, and elastomers, with particular efficacy in polyamide plastics and fibers.Chemical Name

N, N’-hexane-1,6-diylbis(3-(3,5-di-tert.-butyl-4-hydroxyphenylpropionamide))

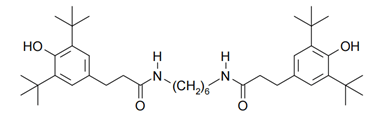

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 637 g/mol Melting Point ℃ 156-161℃ Product Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-1076

Overview

Antioxidant

OX-1076, An efficient, non-staining hindered phenolic antioxidant. Suitable for use in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates. Odorless, light-stable, and resistant to discoloration. It exhibits excellent compatibility with substrates, low volatility, and superior resistance to leaching.Brand

FORNAPLUS

Model No

OX-1076

Industries

Solutions

Application

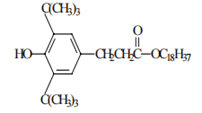

OX-1076, An efficient, non-staining hindered phenolic antioxidant. Suitable for use in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates. Odorless, light-stable, and resistant to discoloration. It exhibits excellent compatibility with substrates, low volatility, and superior resistance to leaching.Chemical Name

Octadecyl-[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]

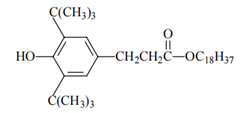

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 530.86 g/mol Melting Point ℃ 50-55℃ Product Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-1010

Overview

Antioxidant

OX-1010, An efficient, non-staining hindered phenolic antioxidant. It can be used in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates.Brand

FORNAPLUS

Model No

OX-1010

Industries

Solutions

Application

OX-1010, An efficient, non-staining hindered phenolic antioxidant. It can be used in plastics, synthetic fibers, elastomers, adhesives, waxes, fats and oils to prevent thermal and oxidative degradation of substrates.Chemical Name

Pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate)

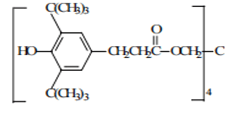

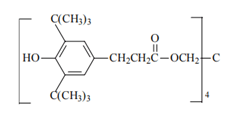

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 1178 g/mol Melting Point ℃ 110-125℃ Product Forms White free-flowing powder Packing Specification 25 kg/bag -

FORNAPLUS OX-245

Overview

Antioxidant

OX-245, A highly efficient hindered phenolic antioxidant, extensively used in various polymers, synthetic fibers, elastomers, adhesives, waxes, oils, and fat-based products to effectively prevent thermal and oxidative degradation of these materials.Brand

FORNAPLUS

Model No

OX-245

Industries

Solutions

Application

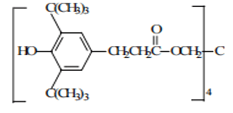

OX-245, A highly efficient hindered phenolic antioxidant, extensively used in various polymers, synthetic fibers, elastomers, adhesives, waxes, oils, and fat-based products to effectively prevent thermal and oxidative degradation of these materials.Chemical Name

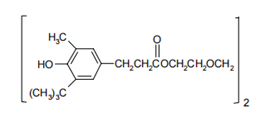

Ethylene bis(oxyethylene) bis-(3-(5-tert-butyl-4-hydroxy-m-tolyl)propionate)

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 586.8g/mol Melting Point ℃ 76-79℃ Product Forms White free-flowing powder Packing Specification 20kg/bag -

FORNAPLUS UV-234

Overview

UV Absorber

UV-234, a high molecular weight phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for many polymers.Brand

FORNAPLUS

Model No

UV-234

Industries

Solutions

Application

UV-234, a high molecular weight phenolic substituted benzotriazole UV absorber that provides good light stabilization protection for many polymers.Chemical Name

Phenol, 2-(2H-benzotriazol-2-yl)-4,6-bis(1-methyl-1-phenylethyl) grade

Chemical Structure

Specifications

Item Typical Value / Properties Molecular Weight 447.6 g/mol Melting Point ℃ 137-141℃ Product Forms Pale yellow powder Packing Specification 20kg/bag

-

TiONA 834

Overview

White Pigment

TiONA® 834 is a blue tint tone, chloride-process, rutile titanium dioxide pigment, designed to provide good optical properties and dispersibility in a wide range of plastic applications where durability is not required.

Key Features:

• Outstanding brightness and whiteness

• Blue tint tone

• Good dispersibility

• Excellent processabilityBrand

TiONA

Model No

834

Industries

Solutions

Application

TiONA® 834 is a blue tint tone, chloride-process, rutile titanium dioxide pigment, designed to provide good optical properties and dispersibility in a wide range of plastic applications where durability is not required.

Key Features:

• Outstanding brightness and whiteness

• Blue tint tone

• Good dispersibility

• Excellent processabilityChemical Name

Titanium Dioxide

-

TiONA 828

Overview

White Pigment

TiONA® 828 is a multi-purpose, blue tint tone, chloride-process, rutile titanium dioxide pigment, designed to give an outstanding combination of ease of dispersion, excellent optical properties and good durability in a wide range of coating and plastic applications.

Key Features:

• High gloss

• Excellent opacity

• High tint strength

• High brightness

• Blue tint tone

• Good durability

• Ease of dispersionBrand

TiONA

Model No

828

Industries

Solutions

Application

TiONA® 828 is a multi-purpose, blue tint tone, chloride-process, rutile titanium dioxide pigment, designed to give an outstanding combination of ease of dispersion, excellent optical properties and good durability in a wide range of coating and plastic applications.

Key Features:

• High gloss

• Excellent opacity

• High tint strength

• High brightness

• Blue tint tone

• Good durability

• Ease of dispersionChemical Name

Titanium Dioxide

-

TiONA 826

Overview

White Pigment

TiONA® 826 is a high performance, multipurpose chloride-process rutile titanium dioxide pigment designed to provide an exceptional combination of ease of dispersion, superior optical properties and very high durability in a wide range of coatings applications. The combination of high tint strength and very high durability of this product makes it also an excellent choice for plastics applications.

Key Features:

• Highest opacity

• Exceptional tint strength

• High gloss

• Superior dispersibility

• Very high durabilityBrand

TiONA

Model No

826

Industries

Solutions

Application

TiONA® 826 is a high performance, multipurpose chloride-process rutile titanium dioxide pigment designed to provide an exceptional combination of ease of dispersion, superior optical properties and very high durability in a wide range of coatings applications. The combination of high tint strength and very high durability of this product makes it also an excellent choice for plastics applications.

Key Features:

• Highest opacity

• Exceptional tint strength

• High gloss

• Superior dispersibility

• Very high durabilityChemical Name

Titanium Dioxide

-

TiONA 595

Overview

White Pigment

TiONA® 595 is a high performance, multipurpose, chloride-process rutile titanium dioxide pigment, most suited in applications requiring good dispersion, durability and optical properties. TiONA® 595 is particularly suited for coatings applications such as PVC plastisols for wallcoverings and spread coatings for flooring where it provides high opacity and low viscosity.

Key Features:

• Superior color stability

• Highest opacity

• High multipurpose durability

• Outstanding brightness and whiteness

• Neutral tint tone

• Superior dispersibility

• Good processabilityBrand

TiONA

Model No

595

Industries

Solutions

Application

TiONA® 595 is a high performance, multipurpose, chloride-process rutile titanium dioxide pigment, most suited in applications requiring good dispersion, durability and optical properties. TiONA® 595 is particularly suited for coatings applications such as PVC plastisols for wallcoverings and spread coatings for flooring where it provides high opacity and low viscosity.

Key Features:

• Superior color stability

• Highest opacity

• High multipurpose durability

• Outstanding brightness and whiteness

• Neutral tint tone

• Superior dispersibility

• Good processabilityChemical Name

Titanium Dioxide

-

TiONA 288

Overview

White Pigment

TiONA® 288 is a blue tint tone, rutile titanium dioxide pigment, manufactured by the advanced chloride process. It has been designed for use in high performance white and tinted polyolefin masterbatch and compounds. The surface treatment provides the optimum combination of high temperature performance with optical efficiency, high pigment loading and ease of dispersion. This ensures TiONA® 288 has excellent processability, making it particularly suitable for high-temperature and dispersion critical film applications.Brand

TiONA

Model No

288

Industries

Solutions

Application

TiONA® 288 is a blue tint tone, rutile titanium dioxide pigment, manufactured by the advanced chloride process. It has been designed for use in high performance white and tinted polyolefin masterbatch and compounds. The surface treatment provides the optimum combination of high temperature performance with optical efficiency, high pigment loading and ease of dispersion. This ensures TiONA® 288 has excellent processability, making it particularly suitable for high-temperature and dispersion critical film applications.Chemical Name

Titanium Dioxide

-

TiONA 233

Overview

White Pigment

TiONA® 233 is a blue tint tone, rutile titanium dioxide pigment, manufactured by the advanced chloride process. Its surface treatment has been optimized to provide the ultimate combination of optical efficiency, dispersion and processing performance along with excellent colour stability/resistance to UV. It is particularly suited for producing highly loaded masterbatches and critical thin films requiring durability.

Key Features:

• Excellent colour stability

• Outstanding dispersion

• Outstanding brightness and cleanliness of mass tone

• Good UV resistance

• Good high temperature processing

• High tint strength with blue tint tone

• HydrophobicBrand

TiONA

Model No

233

Industries

Solutions

Application

TiONA® 233 is a blue tint tone, rutile titanium dioxide pigment, manufactured by the advanced chloride process. Its surface treatment has been optimized to provide the ultimate combination of optical efficiency, dispersion and processing performance along with excellent colour stability/resistance to UV. It is particularly suited for producing highly loaded masterbatches and critical thin films requiring durability.

Key Features:

• Excellent colour stability

• Outstanding dispersion

• Outstanding brightness and cleanliness of mass tone

• Good UV resistance

• Good high temperature processing

• High tint strength with blue tint tone

• HydrophobicChemical Name

Titanium Dioxide

-

TiKON 36

Overview

White Pigment

TiKON™ 36 is a bluish tint tone, sulfate-process, rutile titanium dioxide pigment, designed to provide good optical performance and dispersibility in a wide range of plastics.Brand

TIKON

Model No

36

Industries

Solutions

Application

TiKON™ 36 is a bluish tint tone, sulfate-process, rutile titanium dioxide pigment, designed to provide good optical performance and dispersibility in a wide range of plastics.Chemical Name

Titanium Dioxide

-

FORMOSA K-210

Overview

PVC Impact Modifier

Silicone rubber/acrylate co-polymer FORMOLON K-210 is used for general plastics and engineering plastics. According to well dispersion in resin, it can improve impact strength, surface appearance, help obtain excellent weathering resistance, good processing performance and high productivity, etc.Brand

FORMOSA

Model No

K-210

Application

Silicone rubber/acrylate co-polymer FORMOLON K-210 is used for general plastics and engineering plastics. According to well dispersion in resin, it can improve impact strength, surface appearance, help obtain excellent weathering resistance, good processing performance and high productivity, etc.Specifications

Appearance White Bulk Density (g/cm³) 0.36 min Volatility (%) 1.0 max Foreign Particles (PC/100g) 30 Max Particle Size on 16 mesh sieve (%) 1.0 Max Notched IZOD Impact

(23℃ at Dosage 4% (Kg-cm/cm)40 min Notched IZOD Impact

(-15C at Dosage 4% (Kg-cm/cm)MI

Melt Flow Index (240 ℃ @ 5 kg, 4% addition) (g/10 min) -

FORMOSA M-505

Overview

PVC Impact Modifier

Butadiene series impact modifier M-505Brand

FORMOSA

Model No

M-505

Application

Butadiene series impact modifier M-505Specifications

Appearance White Bulk Density (g/cm³) 0.3 min Volatility (%) 1.0 max Heat Stability 2.0 Tensile Strength (Kg/cm²) 597 Elongation at Break (%) 380 Vicat Temperature (℃) 85.3 Hardness(Shore D) 75-78 -

FORMOSA M-61

Overview

PVC Impact Modifier

Butadiene series impact modifier M-61Brand

FORMOSA

Model No

M-61

Application

Butadiene series impact modifier M-61Specifications

Appearance White Bulk Density (g/cm³) 0.3 min Volatility (%) 1.0 max Heat Stability 3.0 Tensile Strength (Kg/cm²) 541 Elongation at Break (%) 335 Vicat Temperature (℃) 85.7 Hardness(Shore D) 76-78 -

FORMOSA M-51

Overview

PVC Impact Modifier

Butadiene series impact modifier M-51Brand

FORMOSA

Model No

M-51

Application

Butadiene series impact modifier M-51Specifications

Appearance White Bulk Density (g/cm³) 0.3 min Volatility (%) 1.0 max Heat Stability 3.0 Tensile Strength (Kg/cm²) 590 Elongation at Break (%) 358 Vicat Temperature (℃) 85.6 Hardness(Shore D) 75-78 -

FORMOSA M-48

Overview

PVC Impact Modifier

Butadiene series impact modifier M-48Brand

FORMOSA

Model No

M-48

Application

Butadiene series impact modifier M-48Specifications

Appearance White Bulk Density (g/cm³) 0.3 min Volatility (%) 1.0 max Heat Stability 2.5 Tensile Strength (Kg/cm²) 585 Elongation at Break (%) 385 Vicat Temperature (℃) 85.5 Hardness(Shore D) 75-78 -

FORMOSA M-41

Overview

PVC Impact Modifier

Butadiene series impact modifier M-41Brand

FORMOSA

Model No

M-41

Application

Butadiene series impact modifier M-41Specifications

Appearance White Bulk Density (g/cm³) 0.3 min Volatility (%) 1.0 max Heat Stability 3.0 Tensile Strength (Kg/cm²) 570 Elongation at Break (%) 379 Vicat Temperature (℃) 85.2 Hardness(Shore D) 75-78 -

FORMOSA M-31

Overview

PVC Impact Modifier

Butadiene series impact modifier M-31Brand

FORMOSA

Model No

M-31

Application

Butadiene series impact modifier M-31Specifications

Appearance White Bulk Density (g/cm³) 0.3 min Volatility (%) 1.0 max Heat Stability 3.0 Tensile Strength (Kg/cm²) 539 Elongation at Break (%) 338 Vicat Temperature (℃) 86.1 Hardness(Shore D) 76-79 -

FORMOSA C-1250M

Overview

PVC Resin

Matt PVC. Lower gloss value as well as excellent dry mat surface finish.Brand

FORMOSA

Model No

C-1250M

Application

Matt PVC. Lower gloss value as well as excellent dry mat surface finish.Specifications

K value 79.4~81.1 Polymerization Degree 1800±50 Bulk Density (g/c.c) 0.45±0.02 Volatile Matter (%) 0.3↓ -

FORMOSA S-80

Overview

PVC Resin

Suspension PVC with excellent porosity and high ratio of plasticizer absorption enhance the flexibility and elasticity of finish products.Brand

FORMOSA

Model No

S-80

Application

Suspension PVC with excellent porosity and high ratio of plasticizer absorption enhance the flexibility and elasticity of finish products.Specifications

K value 79.4~81.1 Polymerization Degree 1800±50 Bulk Density (g/c.c) 0.45±0.02 Volatile Matter (%) 0.3↓ -

FORMOSA S-75S

Overview

PVC Resin

Suspension PVC with high porosity, good plasticizer absorption and good electrical properties.Brand

FORMOSA

Model No

S-75S

Application

Suspension PVC with high porosity, good plasticizer absorption and good electrical properties. -

FORMOSA S-70

Overview

PVC Resin

Suspension PVC with high porosity, good plasticizer absorption and good electrical properties.Brand

FORMOSA

Model No

S-70

Application

Suspension PVC with high porosity, good plasticizer absorption and good electrical properties.Specifications

K value 69.6~71.5 Polymerization Degree 1250±50 Bulk Density (g/c.c) 0.47±0.02 Volatile Matter (%) 0.3↓ -

FORMOSA S-65S

Overview

PVC Resin

Suspension PVC with good plasticizer absorption and good heat stability.Brand

FORMOSA

Model No

S-65S

Application

Suspension PVC with good plasticizer absorption and good heat stability.Specifications

K value 64.6~66.0 Polymerization Degree 1030±30 Bulk Density (g/c.c) 0.48±0.02 Volatile Matter (%) 0.3↓ -

FORMOSA S-60

Overview

PVC Resin

Suspension PVC with good gelling and very high transparency properties.Brand

FORMOSA

Model No

S-60

Application

Suspension PVC with good gelling and very high transparency properties.Specifications

K value 59.2~60.6 Polymerization Degree 780±30 Ester Content (Wt%) 99.5 min Bulk Density (g/c.c) 0.55±0.02 Volatile Matter (%) 0.3↓ -

FORMOSA P-201

Overview

Processing Aid

General plasticization. Can be use in PVC system.Brand

FORMOSA

Model No

P-201

Application

General plasticization. Can be use in PVC system.Specifications

Appearance White Powder Bulk Density (g/cm³) 0.40 max Volatility (%) 1.0 max Average Particle Size(μm) 100-130 Particle Size(+60 /- 325mesh) 1% / 3%

-

NAN YA SD-8031D

Overview

Liquid octyl tin stabilizer

• Thiol-based stabilizer compliant with food packaging requirements.

• Good initial coloration.

• Good thermal stability, suitable for long-duration high-temperature processing.

• Blending and processing with ABS and MBS can achieve better thermal stability and processability.

• When used together with internal and external lubricants during processing, a synergistic effect can be achieved for better performance.

• No sulfur contamination.Brand

NAN YA

Model No

SD-8031D

Application

• Thiol-based stabilizer compliant with food packaging requirements.

• Good initial coloration.

• Good thermal stability, suitable for long-duration high-temperature processing.

• Blending and processing with ABS and MBS can achieve better thermal stability and processability.

• When used together with internal and external lubricants during processing, a synergistic effect can be achieved for better performance.

• No sulfur contamination.Specifications

Appearance Clear liquid Refractive Index (30℃) 1.4987 ± 0.0020 Specific Gravity (25℃) 14.4 ± 0.4 Viscosity (25℃) cps 300 max -

NAN YA SD-4017BT

Overview

Liquid Butyl Tin Stabilizer

• Good thermal stability, suitable for long-duration high-temperature processing.

• Good transparency and initial coloration.

• Good resistance to sulfur contamination.

• Blending and processing with ABS and MBS can achieve better thermal stability and processability.

• When used together with internal and external lubricants during processing, a synergistic effect can be achieved for better performance.Brand

NAN YA

Model No

SD-4017BT

Application

• Good thermal stability, suitable for long-duration high-temperature processing.

• Good transparency and initial coloration.

• Good resistance to sulfur contamination.

• Blending and processing with ABS and MBS can achieve better thermal stability and processability.

• When used together with internal and external lubricants during processing, a synergistic effect can be achieved for better performance.Specifications

Appearance Clear liquid Refractive Index (30℃) 1.502 – 1.508 Specific Gravity (25℃) 14.6 – 15.6 Viscosity (25℃) cps 250 max -

NAN YA PCX-05CEA

Overview

Putty-type calcium-zinc stabilizer

• Non-toxic, environmentally friendly stabilizer.

• Excellent thermal stability and transparency

• Good plasticization and dispersibility.

• When used together with epoxy, excellent results can be achieved.

• No sulfur contamination.Brand

NAN YA

Model No

PCX-05CEA

Application

• Non-toxic, environmentally friendly stabilizer.

• Excellent thermal stability and transparency

• Good plasticization and dispersibility.

• When used together with epoxy, excellent results can be achieved.

• No sulfur contamination.Specifications

Appearance Clear liquid Refractive Index (30℃) 1.4987 ± 0.0020 Specific Gravity (25℃) 14.4 ± 0.4 Viscosity (25℃) cps 300 max -

NAN YA LQX-39PT

Overview

Liquid barium zinc stabilizer

• An environmentally friendly stabilizer free of nonylphenol and dipropylene glycol (2P free).

• Can replace cadmium-barium-zinc liquid stabilizer products.

• High-concentration self-slipping stabilizer that can reduce stabilizer usage by 30–40%.

• Has excellent heat resistance and initial coloring.

• When used together with epoxy, excellent results can be achieved.Brand

NAN YA

Model No

LQX-39PT

Application

• An environmentally friendly stabilizer free of nonylphenol and dipropylene glycol (2P free).

• Can replace cadmium-barium-zinc liquid stabilizer products.

• High-concentration self-slipping stabilizer that can reduce stabilizer usage by 30–40%.

• Has excellent heat resistance and initial coloring.

• When used together with epoxy, excellent results can be achieved.Specifications

Appearance Clear liquid with orange-yellow to orange-red color Refractive Index (30℃) 1.4870 ± 0.005 Specific Gravity (25℃) 1.04 ± 0.03 Viscosity (25℃) cps 300 max -

NAN YA LQX-19T

Overview

Liquid barium zinc stabilizer

• Good initial coloration, suitable for white high-temperature vulcanized products.

• Can replace cadmium-barium-zinc liquid stabilizer products.

• Self-lubricating stabilizer, can be used alone; generally, no additional powder stabilizer or lubricant is needed during processing.

• When used together with epoxy, excellent results can be achieved.Brand

NAN YA

Model No

LQX-19T

Application

• Good initial coloration, suitable for white high-temperature vulcanized products.

• Can replace cadmium-barium-zinc liquid stabilizer products.

• Self-lubricating stabilizer, can be used alone; generally, no additional powder stabilizer or lubricant is needed during processing.

• When used together with epoxy, excellent results can be achieved.Specifications

Appearance Clear liquid with orange-yellow to orange-red color Refractive Index (30℃) 1.4795 – 1.4895 Specific Gravity (25℃) 1.041 – 1.081 Viscosity (25℃) cps 250 max -

NAN YA TOTM

Overview

PVC Plasticizer

TOTM is synthesized through the esterification of 2-ethylhexanol and trimellitic anhydride. It features low volatility, low migration, excellent electrical resistance, and outstanding heat resistance. When used in wire and cable applications, TOTM can meet the UL 62 105°C temperature rating in the United States. In PVC plastisols, TOTM-based formulations exhibit lower viscosity than those using DIDP under the same softness conditions. In terms of stability, compared with DEHP, TOTM plastisols show less variation, indicating better long-term stability.Brand

NAN YA

Model No

TOTM

Application

TOTM is synthesized through the esterification of 2-ethylhexanol and trimellitic anhydride. It features low volatility, low migration, excellent electrical resistance, and outstanding heat resistance. When used in wire and cable applications, TOTM can meet the UL 62 105°C temperature rating in the United States. In PVC plastisols, TOTM-based formulations exhibit lower viscosity than those using DIDP under the same softness conditions. In terms of stability, compared with DEHP, TOTM plastisols show less variation, indicating better long-term stability.Chemical Name

Tris(2-ethylhexyl) trimellitate / TOTM / Trioctyl trimellitate / TEMTM

Specifications

CAS 3319-31-1 Color (APHA) 50 max Acid Value (mg KOH/g) 0.10 max Ester Content (Wt%) 99.0 min Insulation Resistance 30°C (Ω-cm) 3.0 X 1011 Heat Loss 125℃ ± 3℃ X 3hrs (Wt%) 0.10 max Specific Gravity 20/20℃ 0.991 ± 0.003 Refractive Index 25℃ 1.484 ± 0.003 Moisture (Wt%) 0.05 max 0.05 max 20.0 × 10¹¹ Phthalate Content (Wt%) 0.015 max Saponification value (mg KOH/g) 308 ± 5 Antioxidant (Wt%) 0.35 ± 0.05 Phthalate Content (ppm) 350 -

NAN YA DOTP

Overview

PVC Plasticizer

DOTP is synthesized by esterification of isooctanol and terephthalic acid. It is a non-phthalate plasticizer and an environmentally friendly plasticizer. It is not listed as a restricted chemical substance in EU countries. DOTP has good compatibility with PVC, excellent processing performance, and offers superior thermal aging stability.Brand

NAN YA

Model No

DOTP

Application

DOTP is synthesized by esterification of isooctanol and terephthalic acid. It is a non-phthalate plasticizer and an environmentally friendly plasticizer. It is not listed as a restricted chemical substance in EU countries. DOTP has good compatibility with PVC, excellent processing performance, and offers superior thermal aging stability.Chemical Name

Diisooctyl Terephthalate (DOTP) / Di-2-Ethylhexyl Terephthalate / Dioctyl Terephthalate

Specifications

CAS 6422-86-2 Color (APHA) 25 max Acid Value (mg KOH/g) 0.03 max Ester Content (Wt%) 99.5 min Heat Loss 125℃ ± 3℃ X 3hrs (Wt%) 0.10 max Specific Gravity 20/20℃ 0.984 ± 0.003 Phthalate Content (Wt%) 0.015 max Refractive Index 25℃ 1.488 ± 0.003 Moisture (Wt%) 0.05 max Insulation Resistance 30°C (Ω-cm) 20.0 × 10¹¹ -

NAN YA DINP

Overview

PVC Plasticizer

DINP (Diisononyl Phthalate) is produced by esterifying isononanol with phthalic anhydride. In many aspects, DINP’s plasticizing properties are similar to those of DEHP. However, DINP’s low volatility gives it advantages in certain applications. As a general-purpose plasticizer, compared to DEHP, DINP exhibits lower plasticizing efficiency, lower migration, lower water extraction rate, and slightly higher gelation temperature and electrical resistance. Its low volatility not only helps extend product lifespan but also reduces evaporation and volatilization during processing.Brand

NAN YA

Model No

DINP

Application

DINP (Diisononyl Phthalate) is produced by esterifying isononanol with phthalic anhydride. In many aspects, DINP’s plasticizing properties are similar to those of DEHP. However, DINP’s low volatility gives it advantages in certain applications. As a general-purpose plasticizer, compared to DEHP, DINP exhibits lower plasticizing efficiency, lower migration, lower water extraction rate, and slightly higher gelation temperature and electrical resistance. Its low volatility not only helps extend product lifespan but also reduces evaporation and volatilization during processing.Chemical Name

Diisononyl phthalate (DINP)

Specifications

CAS 68515-48-0 ; 28553-12-0 Color (APHA) 25 max Acid Value (mg KOH/g) 0.05 max Ester Content (Wt%) 99.6 min Insulation Resistance 30°C (Ω-cm) 3.0 X 1011 Heat Loss 125℃ ± 3℃ X 3hrs (Wt%) 0.10 max Specific Gravity 20/20℃ 0.978 ± 0.003 Refractive Index 25℃ 1.484 ± 0.003 Moisture (Wt%) 0.05 max -

NAN YA DEHP

Overview

PVC Plasticizer

DEHP (DOP) is produced by the esterification of isooctanol with phthalic anhydride. DEHP has excellent compatibility with PVC, high plasticizing efficiency, and combines the average performance characteristics of various plasticizers. It is the most widely used plasticizer in PVC processing. Specifications include General Grade A, Insulation Grade B, and Glove Grade C.

Brand

NAN YA

Model No

DEHP

Application

DEHP (DOP) is produced by the esterification of isooctanol with phthalic anhydride. DEHP has excellent compatibility with PVC, high plasticizing efficiency, and combines the average performance characteristics of various plasticizers. It is the most widely used plasticizer in PVC processing. Specifications include General Grade A, Insulation Grade B, and Glove Grade C.

Chemical Name

Diisooctyl Phthalate / DEPH / DOP / Di-2-Ethylhexyl Phthalate

Specifications

CAS 117-817 Color (APHA) 25 max Acid Value (mg KOH/g) 0.05 max Ester Content (Wt%) 99.6 min Insulation Resistance 30°C (Ω-cm) 3.0 X 1011 Heat Loss 125℃ ± 3℃ X 3hrs (Wt%) 0.10 max Specific Gravity 20/20℃ 0.986 ± 0.003 Refractive Index 25℃ 1.485 ± 0.003 Moisture (Wt%) 0.05 max -

NAN YA DEHA

Overview

PVC Plasticizer

DOA is produced by esterifying 2-ethylhexanol with adipic acid and is a non-phthalate plasticizer. It offers excellent low-temperature properties and favorable characteristics in PVC plastisols, making it the most widely used cold-resistant plasticizer. Compared to DEHP, DOA has a higher volatility under similar softness conditions. Due to its relatively low electrical resistance, DOA is suitable for antistatic processing applications such as conveyor belts and flooring materials.

Complies with FDA: 21 CFR 175.105Brand

NAN YA

Model No

DEHA

Application

DOA is produced by esterifying 2-ethylhexanol with adipic acid and is a non-phthalate plasticizer. It offers excellent low-temperature properties and favorable characteristics in PVC plastisols, making it the most widely used cold-resistant plasticizer. Compared to DEHP, DOA has a higher volatility under similar softness conditions. Due to its relatively low electrical resistance, DOA is suitable for antistatic processing applications such as conveyor belts and flooring materials.

Complies with FDA: 21 CFR 175.105Chemical Name

Di-(2-Ethylhexyl) Adipate / DEHA / Dioctyl Adipate / DOA

Specifications

CAS 84-71-9 Color (APHA) 25 max Acid Value (mg KOH/g) 0.05 max Ester Content (Wt%) 99.5 min Heat Loss 125℃ ± 3℃ X 3hrs (Wt%) 0.10 max Specific Gravity 20/20℃ 0.958 ± 0.003 Refractive Index 25℃ 1.460 ± 0.003 Moisture (Wt%) 0.05 max Phthalate Content (Wt%) 0.015 max -

NAN YA 911P

Overview

PVC Plasticizer

911P is produced by esterifying C9~C11 mixed alcohol and Phthalic Anhydride. 911P has low volatility and excellent cold resistance. Its cold resistance is equivalent to that of a DEHP/ DOA mixture at 60/40WT%. Regarding wire and cable heat resistance, 911P has durable mechanical characteristics and excellent cold resistance. Mixing 911P with TOTM can provide a more economical way to meet the U.S.’s UL 62 105℃ class cable requirement. 911P’s low volatility is especially recommended for “non-fogging” products, such as leather coats, spring cushions for cars, etc.Brand

NAN YA

Model No

911P

Application

911P is produced by esterifying C9~C11 mixed alcohol and Phthalic Anhydride. 911P has low volatility and excellent cold resistance. Its cold resistance is equivalent to that of a DEHP/ DOA mixture at 60/40WT%. Regarding wire and cable heat resistance, 911P has durable mechanical characteristics and excellent cold resistance. Mixing 911P with TOTM can provide a more economical way to meet the U.S.’s UL 62 105℃ class cable requirement. 911P’s low volatility is especially recommended for “non-fogging” products, such as leather coats, spring cushions for cars, etc.Chemical Name

Di-(C9-C11) Phthalate (911P)

Specifications

CAS 68515-43-5 Color (APHA) 25 max Acid Value (mg KOH/g) 0.05 max Ester Content (Wt%) 99.5 min Heat Loss 125℃ ± 3℃ X 3hrs (Wt%) 0.10 max Specific Gravity 20/20℃ 0.960 ± 0.003 Refractive Index 25℃ 1.481 ± 0.003 Moisture (Wt%) 0.05 max Acid Value after Heating 125 ℃ ± 3 ℃ × 3 hrs (mg KOH/g) 0.20 max